Tire scanning and traceability system - Datalogic STS320

STS320 is a specialized industrial scanning system designed exclusively for the tire industry. It enables reliable tire identification, traceability and sorting throughout the tire lifecycle – from vulcanization to quality testing to logistics and distribution.

01/

What is the STS320 system for the tire industry

The STS320 is a complete, factory-integrated scanning system designed for the most demanding identification applications in the tire industry. The solution is designed for stable reading of codes on tires moving at high speeds, in variable orientation and in harsh environmental conditions.

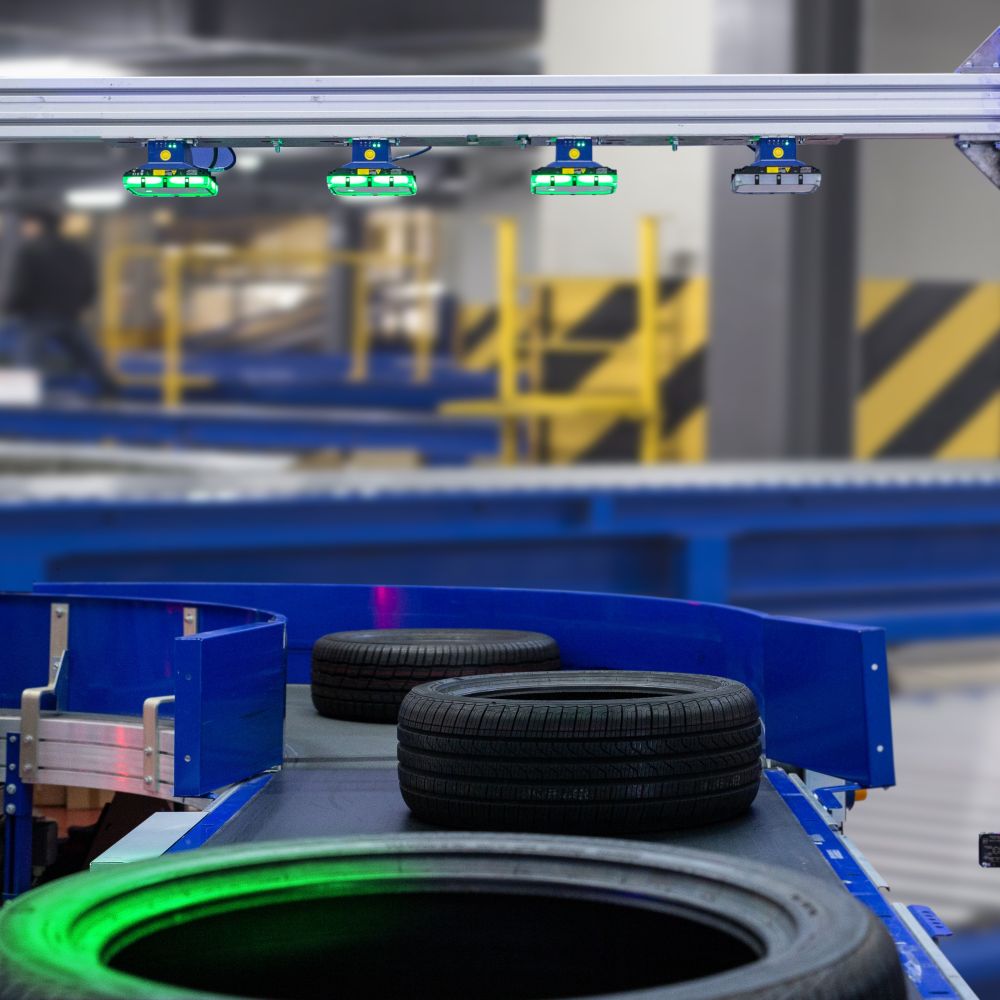

The system consists of multiple reading heads integrated into a single scanning frame, ready for installation above the conveyor. It provides a very large field of view (more than 1,200 mm), high depth of field, and the ability to realize top reading, side reading and bottom reading, which is crucial in tire sorting and testing lines.

Scanning technology and system architecture

The STS320 uses 2 MP matrices, powerful processors and dedicated illumination systems optimized for difficult black rubber surfaces, embossed characters, labels and DPM codes. The system enables stable reading of 1D and 2D codes, as well as direct markings, even in low contrast and dirty conditions.

The solution’s architecture is designed as an “out-of-the-box” system:

- pre-configured,

- factory tested,

- Ready to work in an industrial environment.

The system offers advanced diagnostics, image storage, “no-read” case classification, a web interface for remote monitoring, and analytical tools to support continuous optimization of the production process.

02/

Application in tire production and logistics

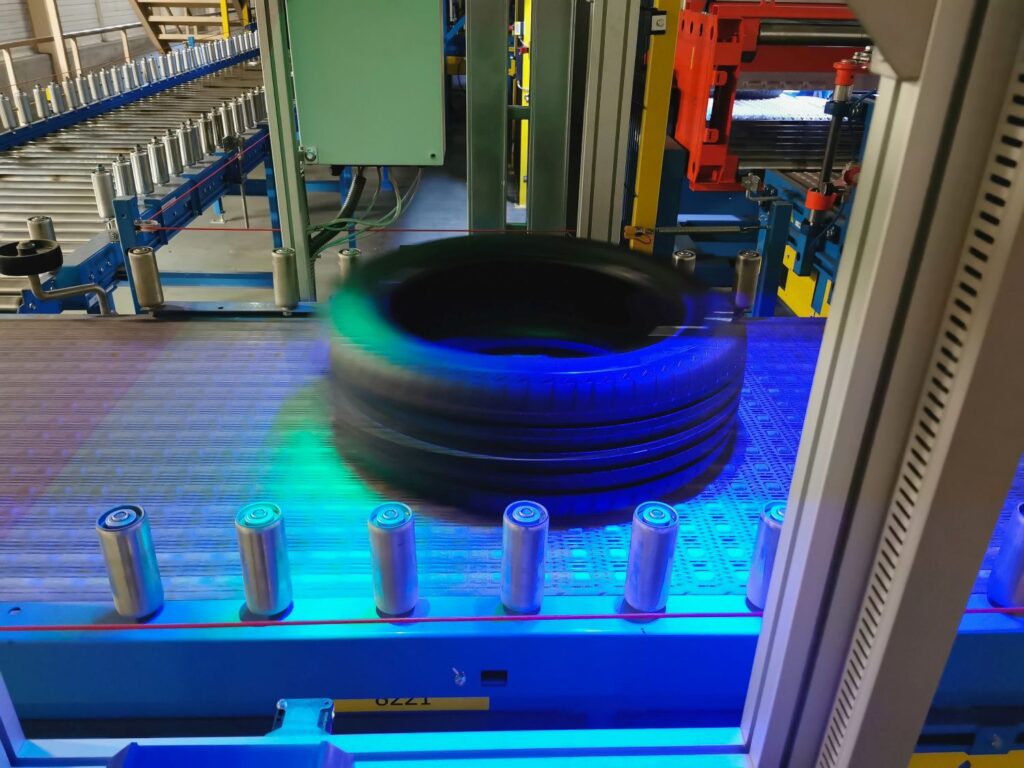

The STS320 system is used throughout the tire’s life cycle – both in production processes and in internal logistics and distribution.

The most common application areas include:

- vulcanization (green & cured tires) – linking the tire to the formulation, press, mold and batch,

- Production traceability – full traceability of every tire on the line,

- High-speed sorting – automatic tire reading and routing on multidirectional conveyors,

- Test lines and quality control – linking test results to a specific tire,

- tire construction and assembly machinery – identification of components and finished products,

- Picking and picking stations – handling distribution centers,

- warehouses and logistics – tracking the flow of tires and wheels,

- visual inspection – support of quality control and image archiving systems.

03/

STS320 is the standard in the tire industry

The STS320 meets the stringent requirements of tire plants, where the following are crucial:

- 24/7 continuous operation of the system,

- Resistance to sulfur, dust, vibration and harsh environmental conditions,

- very high reading efficiency,

- Full integration with PLC and production and IT systems.

With multi-head configurations, support for passenger and truck tires, and bottom reading capabilities, the STS320 system is the market standard for tire manufacturers building advanced traceability and sorting automation systems.

04/

Key features of the STS320 system