Read more >>

What makes our WMS software different?

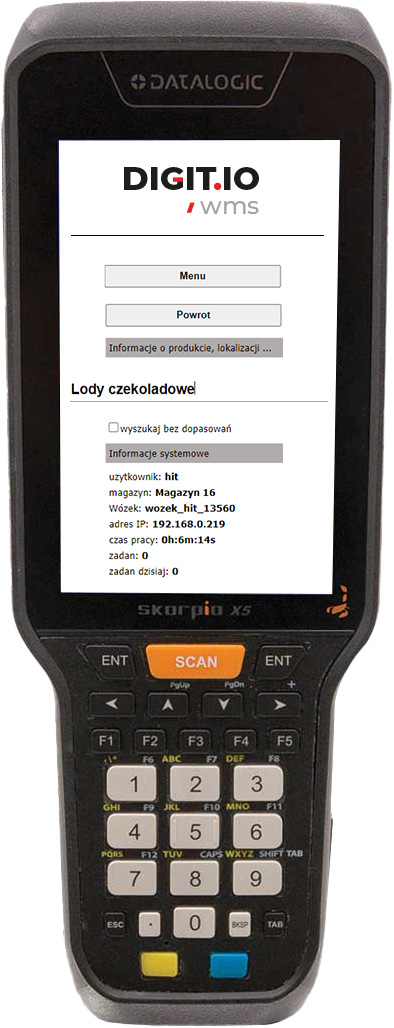

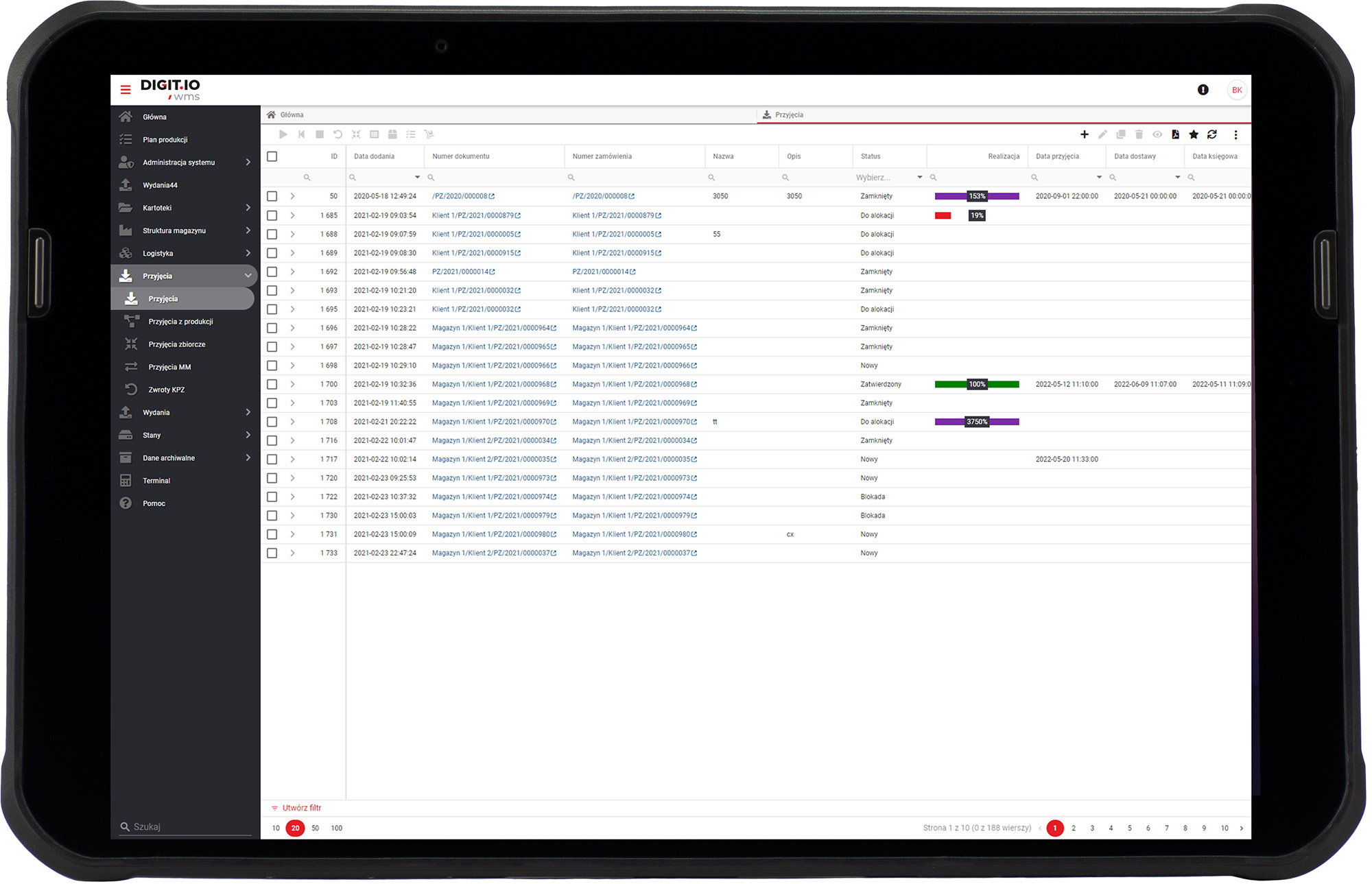

We offer two solutions tailored to different business needs – the proprietary Digit.IO WMS system and the global Blue Yonder WMS. Each is based on modern technologies, guarantees reliability and data security. Our WMS systems allow full configuration of processes, definition of internal transport paths and personalization of the user interface. This allows the system to perfectly reflect the structure of your warehouse.

How is the implementation of a WMS going?

We handle the process comprehensively – from analysis and audit, through functional design, to user training and post-implementation service. Our team of experts supports you at every stage so that the WMS system covers all key processes in your company. The implementation is done in stages, so you maintain continuity of work and minimize the risk of downtime.

What does WMS stand for by its acronym?

WMS – the abbreviation comes from Warehouse Management System – which is a warehouse management system. The software controls the movement of goods, monitors resources and improves cooperation between departments. In practice, the WMS becomes the command center of the warehouse – it automates tasks, distributes work and analyzes data, allowing you to make fact-based decisions.

Who is the WMS program designed for?

Our solution is ideal for both large distribution centers and medium-sized retail or manufacturing companies. Thanks to its modular design, it can be easily adapted to the specifics of the business and industry requirements, regardless of the size or complexity of the processes. A WMS warehouse system works well for any organization that focuses on growth, precision and security of operations.

With our solution you can:

- Manage multiple warehouses from a single system,

- Monitor inventory in real time and plan deliveries in advance,

- Integrate data with ERP, e-commerce and warehouse automation systems,

- Control employee productivity and track the flow of goods,

- Analyze key indicators and make data-driven decisions.

Thanks to its flexible configuration, a WMS warehouse system grows with your business, allowing you to introduce new features and modules without having to replace the entire software. It’s a solution that not only automates logistics, but also supports your company’s growth strategy.

Bet on proven WMS software

With us, you will automate every stage of warehouse operations and gain full control over logistics processes. We have been implementing WMS systems for years, which realistically increase efficiency and reduce errors in order handling. We also offer MDM systems for managing fleets of mobile devices.

Contact us and see how our WMS can optimize your warehouse operations, increase team efficiency and give your company a competitive advantage.