Shortcuts

- New technologies are important, but the basics should not be forgotten

- Masterdata – product master data feeding the WMS system.

- Masterdata vs. WMS – the processes of receiving and storing goods in the warehouse

- Masterdata vs WMS – picking and releasing goods from the warehouse

- Our core data support program

- Highlights

New technologies are important, but the basics should not be forgotten

It is clear that new technologies are transforming the warehouse into a system-controlled organism, with highly efficient computing units performing hundreds of analyses per second, suggesting the best possible scenarios. However, there is one piece of the logistics puzzle that we often forget about, and that is the so-called “MASTERDATA. MASTERDATA.

What is it, how to properly take care of it, and what might be the consequences of neglecting to manage it?

Masterdata - product master data feeding the WMS system

Masterdata is nothing more than a set of master data about each product in the warehouse. This data primarily includes:

- Product name

- Manufacturer’s name

- Product code

- Best-before date

- Type of packaging

- Product Variant

- Information on optional serial numbers, or lot numbers

- Product weight and dimensions

Gathering all the master data can be time-consuming, and not every supplier shares it willingly with its customer. The reason for this is primarily the lack of standards for storing them. Some hope for changing this state of affairs is the idea of an Electronic Product Passport promoted by the GS1 Organization.

There is no denying that the availability of master data greatly improves the performance of a WMS, and is even essential to its operation.

Masterdata vs. WMS - the processes of receiving and storing goods in the warehouse

The WMS uses master data in several functional areas, so the number of errors in warehouse processes is significantly reduced.

- Receipt of goods: at this stage, the system can check and possibly correct the correctness of all master data, especially those that will affect later elements of the warehouse puzzle (e.g., shelf life data may affect picking in accordance with the FEFO strategy).

- The process of storing goods: the basic data about the weight and type of packages are a safeguard in the area of proper storage of goods on the racks, so that, for example, we will not allow them to be overloaded

Masterdata vs WMS - picking and releasing goods from the warehouse

- Master data in the picking process: the availability of relevant data will allow the construction and application of appropriate picking strategies in accordance with specific customer requirements.

- Master data and its impact on repackaging and shipping: complete and quality master data influences the use of optimal shipping packaging, so that the shipping itself can be cheaper and the customer’s shopping experience simply better. The issue of packaging is also not without its impact on the environment.

Our core data support program

At HKK Group, we recognize the importance of master data to your business, which is why the IT systems we design and implement work to take full advantage of its potential.

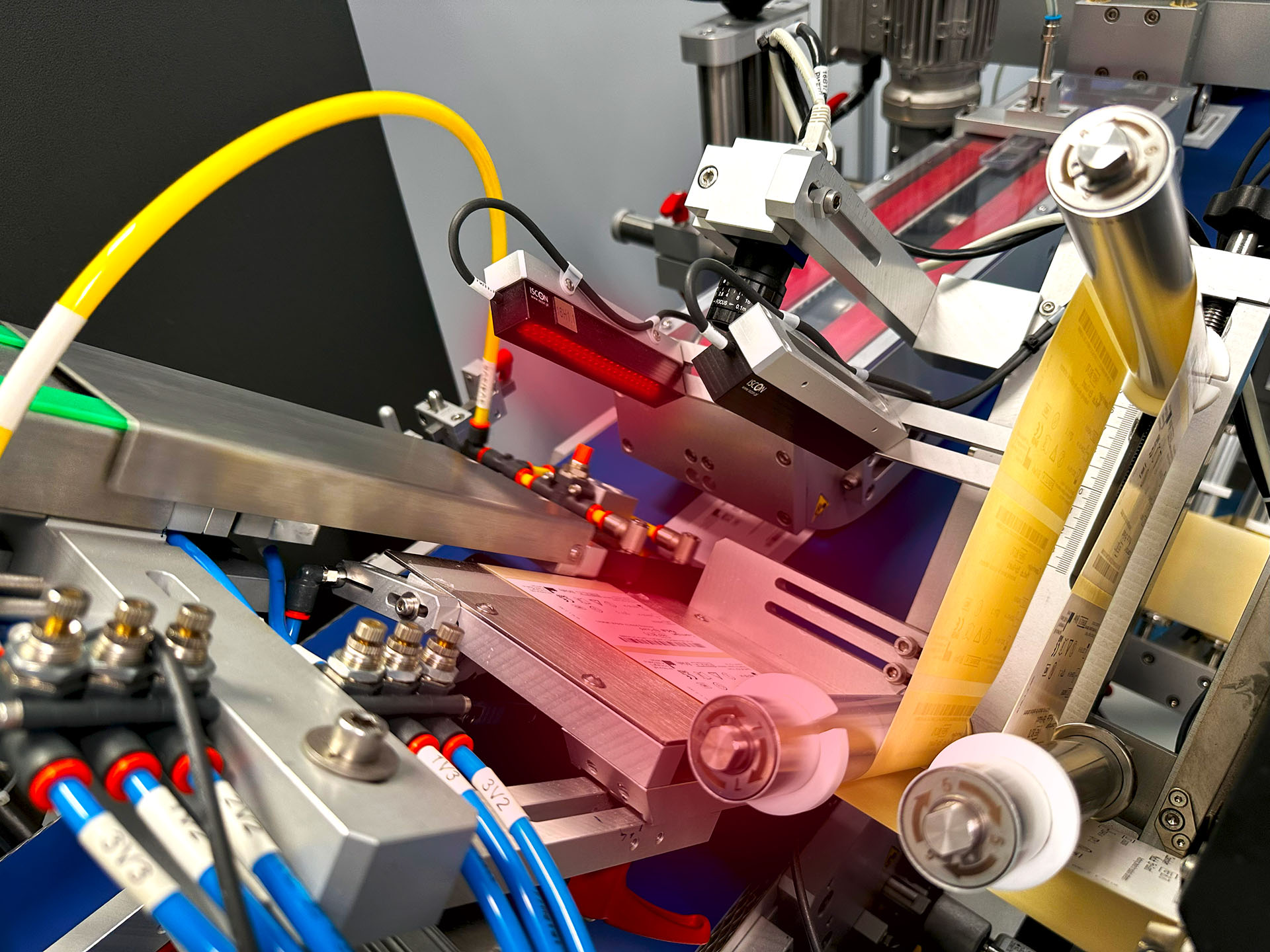

We also offer comprehensive support in the process of standardizing master data. Using professional Cubiscan brand logistics dimensioning equipment (e.g. Cubiscan 325), we accurately measure and weigh each unit of product.

In the next step, we enrich the database with high-quality product photos and update the master date, taking into account additional customer-specific information.