Automation equipment

Automation in logistics today is not an option, but a necessity. If you want your business to grow harmoniously and be more competitive, bet on innovative equipment and solutions. At HKK Group, we have prepared an offer tailored to the needs of both thriving international companies and local businesses.

Automatic barcode reading, machine vision and vision systems, automatic quality control, print & apply systems, RFID gateways. We implement solutions from our partners Datalogic, CAB, Zebra, OMRON.

01/

Automation is NOW

In a world of rising employment costs and ongoing shortages of skilled personnel, it is becoming essential to reach for process automation solutions.

In order to properly identify the potential for automation, look for task repetition. If work in certain areas bears such hallmarks, it is more than likely to be automated. Trust our specialists to help you plan your logistics processes with innovative tools. We design solutions tailored to your needs, the specifics of your business and your budget.

Logistics automation makes it possible:

- precise process planning,

- Optimization of resource consumption,

- Effective time management,

- To accomplish the same tasks in less time.

In addition, it provides a remedy for labor shortages, which are becoming increasingly common in most industries.

What do we offer?

Production processes and logistics operations do not recognize compromise.

The solutions designed by my department, meet the needs of organizations of all scales, starting from international airports, to large logistics centers and factories, to small and medium-sized companies operating locally.

Each industry has its own unique challenges, but our solutions are tailored to each. Regardless of the scale of implementation, we ensure the highest quality, professionalism and meeting the deadline. We know that in the dynamically changing world of business, you need to act fast. On the other hand, we make sure that every device we deliver meets the highest quality standards. We have extensive experience in serving entities in various industries that require us to take a completely different approach. Our priority is customer satisfaction, which is why we make every effort to ensure that both the planning and implementation of the selected solutions go smoothly.

Wojciech Stachowiak, Head of Automation Solutions Department

15 years

We rely on the reliable technology of our partners:

02/

Overview of solutions and case studies

Datalogic AV7000 - an advanced and comprehensive solution for automatic identification of goods.

Introducing a high-resolution industrial desktop code scanner designed for fast, reliable and versatile identification of goods.

Thanks to advanced scanning technology, the reader guarantees fast and accurate reading of both one-dimensional and two-dimensional codes.

Key features of the solution include:

Case study - a case study

Challenge

An e-commerce logistics company was experiencing delays in its warehouse collection process due to the performance of crossbelt conveyors that moved shipments at speeds of up to 3 meters per second.

Link

One of the key features of the AV7000 that has helped improve warehouse processes is its image analysis capability. With this solution, the company was able to monitor and analyze in real time the movement of shipments on the conveyor belt, making it possible to quickly detect possible problems, such as stopped shipments or damage to packages.

In addition, the company decided to use the WebSentinel solution, which is part of the Datalogic AV7000 platform. WebSentinel is an advanced data analysis tool that allows you to monitor process performance, identify areas that need optimization, and generate reports and statistics.

Effects

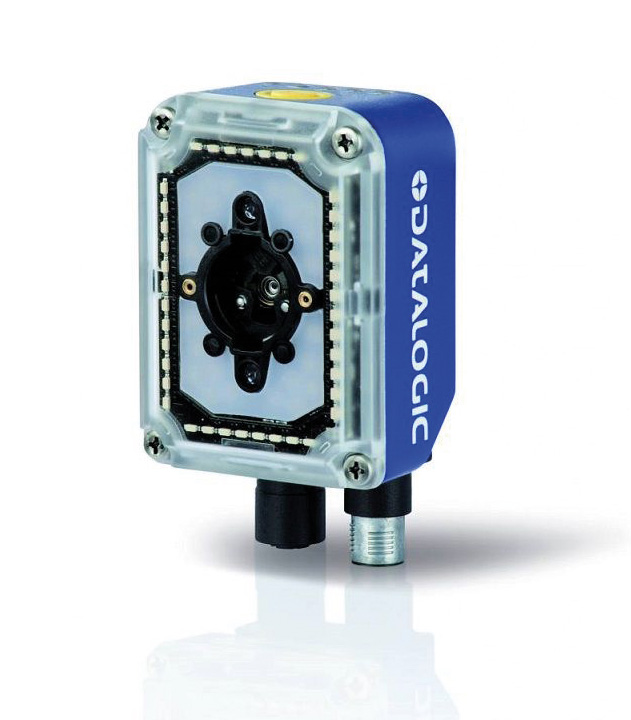

Datalogic Matrix 320

in optimizing the print & apply automatic labeling process.

Providing a reading efficiency of 99%, the Matrix 320 guarantees reliability in identifying barcodes on labels. The speed of the reader allows seamless integration into the “print & apply” process without generating delays.

Advantages of the Matrix 320 reader

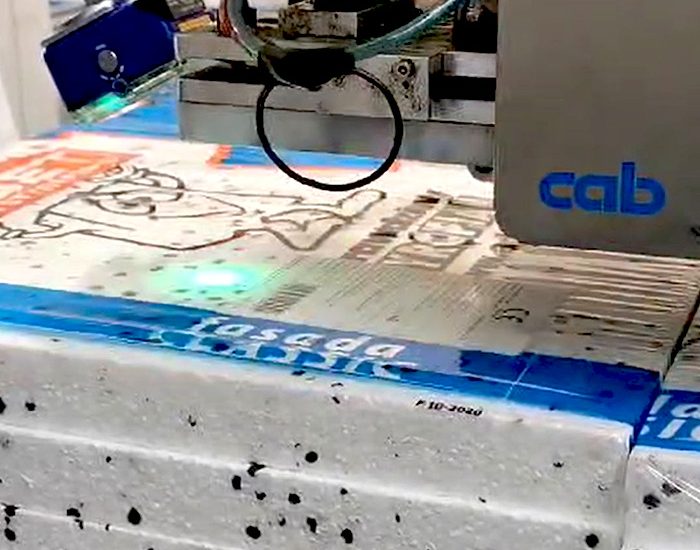

Case study - case study - ARBET SP.J.

The implementation of the Datalogic Matrix 300N reader in the “print & apply” process has brought tangible benefits to the polystyrene foam manufacturer ARBET of Koszalin.

With a reading efficiency of 99% and a foot-mounted applicator, the company has achieved significant improvements in the precision and speed of the labeling process.

Significant reductions in errors have contributed to increased production efficiency, and automatic integration with the WMS has allowed for better data management and real-time process tracking. In addition, the installation of a reader on the foot of the applicator enabled a smoother and more automated operation, minimizing the risk of damage or errors due to human intervention.

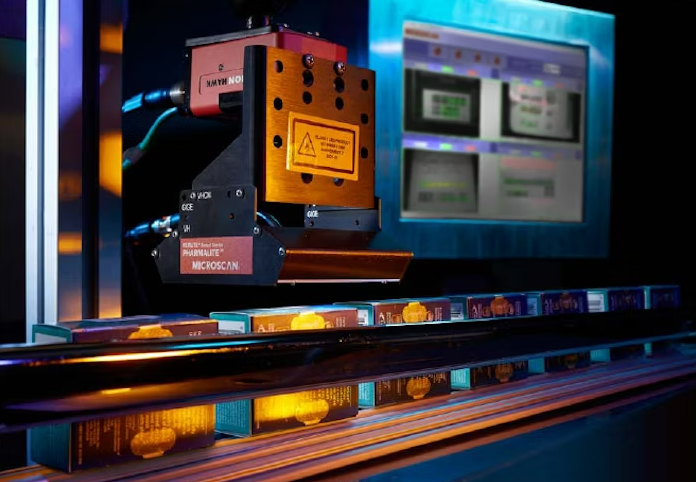

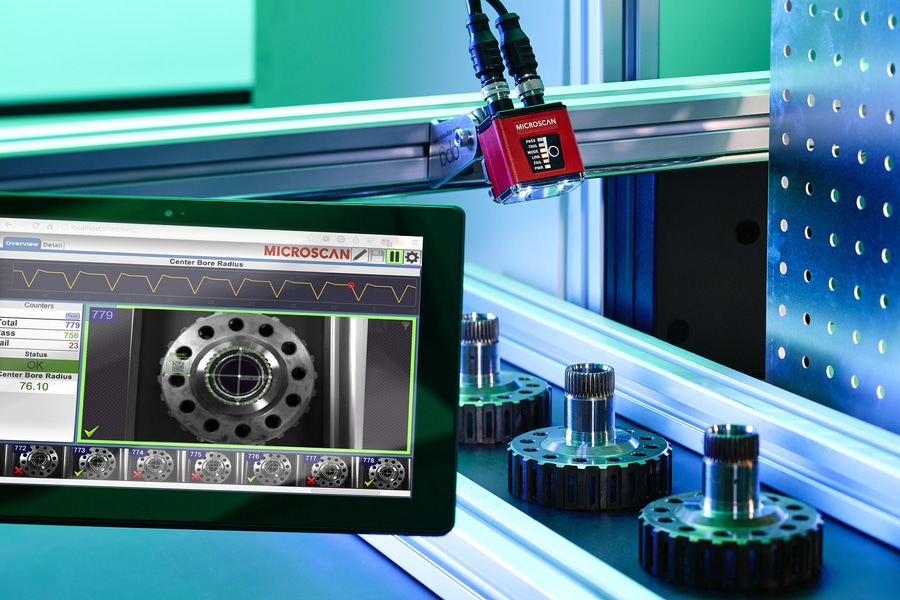

Vision Hawk Microscan camera inspection of label content and product quality

.

Microscan’s Vision Hawk device has many advantages that make it an ideal tool dedicated to automatic quality control.

In the case presented here, we are talking about an application involving verification of the contents of self-adhesive labels, during the manufacturing processes of automotive parts.

Key features of the solution include:

Case study - a case study

The implementation of the Vision Hawk Microscan smart camera in the label content verification and quality control process has brought significant benefits to the auto parts manufacturer.

Thanks to the high reading precision and speed of the camera, the company has achieved an improvement in labeling quality and also a significant acceleration of the quality control process for the products themselves.

Verification of the labels after application allowed quick identification of any errors, minimizing the risk of releasing defective products into the market. Integration of the camera with OCR and barcode reading has enabled comprehensive inspection of label contents, ensuring compliance with industry regulations and production standards.

Datalogic Matrix 320X - automatic system for reading codes from bulk packages on a pallet.

In the example described here, we present a system consisting of 16 Datalogic Matrix 320X readers, mounted on a rectangular-shaped frame.

Advantages of the Matrix 320X reader

Case study - a case study

The implementation of an automated system for reading codes from palletized packaging using Datalogic Matrix 320 readers has brought significant benefits to the food manufacturer.

Thanks to the high reading performance and precise operation of the readers, the company has achieved a significant improvement in the efficiency of the product identification process at the warehouse receiving stage.

The automatic transfer of the read data to the WMS system made it possible to quickly update inventory information and monitor the flow of goods in the warehouse on an ongoing basis. In addition, automatic generation of bulk labels based on the read data allowed streamlining the process of product labeling, while minimizing the risk of errors.

Datalogic ATR - automatic baggage identification system in airport automation.

For many years we have been involved in the implementation of automatic baggage identification systems ATR (Automatic Tag Reading). The solution enables automated sorting of suitcases in airport baggage handling systems.

Datalogic ATR allows you to meet the requirements of the most demanding airport applications. This system makes it possible to read the information contained on the label without the need for baggage detention or operator intervention in the process. The essence of the system’s operation is to read the barcode regardless of its location on the luggage.

This is made possible by building a tunnel of Datalogic DS8110 and DX8210 laser devices. Proper installation of the readers and the use of patented technologies such as ACR™ (advanced code reconstruction system) and PackTrack™ (code-to-product assignment system), ensure maintenance-free operation, high reading level and high speed. The system’s performance meets the requirements of the recommended IATA 1740a practice.

Feedback from the ATR can be sent to customer systems via serial communication or using other available industrial data transmission protocols.

Types of ATR systems

Depending on the purpose of the Datalogic ATR in the baggage handling system, it comes in the following options:

- ATR 360° – reading from 6 sides (front, back, up, down, right, left), typical application: installation on conveyor belts.

- ATR 270° – reading from 5 sides (front, back, top, right, left), typical application: mounting on tilt¬-tray sorters.

- ATR 90° – reading from 1 side (bottom), typical application: installation on sorter inlet lines.

As an added benefit, the ATR can be linked to Datalogic’s WebSentinel™ Plus server software for viewing, status control, statistics, and aggregating data from all reading points in a given system.

Case study - a case study

Deployments in the airport industry require the highest system performance, very high efficiency and reliability.

In the described deployment, different types of ATRs were used. A360° AT R was installed in front of hazardous and prohibited material detectors.

ATR 270° was installed on an automatic tilt-tray sorter along with ATR 90° stations on the sorter’s inlet lines.

Support the order picking process using warehouse automation components .

Based on our years of experience, we implement innovative warehouse automation solutions to support order picking processes prior to shipment to the customer.

Automated systems based on reading 1D, 2D codes or RFID technology, provide assurance of the correct contents of a given order, reduce the possibility of human error, and lead to resource savings. Such solutions increase the efficiency of the operation of the entire automation system, as well as improve the quality of process control.

An additional advantage is the ability to expand the system’s functionality with Datalogic WebSentinel™ Plus server software. The package allows viewing, status control, statistics, and also aggregates data from all reading points in a given system. The system can also be expanded by using Datalogic DM3610 dimensioning devices. This configuration is able to provide the dimensions of a given product “on the fly,” without having to stop the line.

Solutions of this type are used at the end of production lines, warehouse systems or e-commerce customers, among others.

Case study - a case study

In order to increase the efficiency of the system and meet the ever-increasing demands of end customers, our client decided to invest in installing a scanning gateway consisting of three Datalogic DX8210 devices.

The implemented configuration allowed us to cover all the surfaces on which the barcode is placed, so we could guarantee a high level of reading, without having to position the packages.

Products from the finished product warehouse are transported by a conveyor system to the automatic sorter area , where a set of Datalogic scanners has been installed.

As the product passes through the reading field, the code is recognized and sent to the host system, which gives the shipment the appropriate destination. The statistics available in real time allow efficient monitoring of the performance of the release area.

The components of a given order are routed to a specific drop-off and are then packed by operators into bulk packages.

Effects

Logistics robots

03/

Learn about autonomous mobile robots

Increase productivity and unleash power. Transform your workspace with a flexible, scalable and quick-to-deploy AMR solution.

04/

Downloads / Testimonials

Thanks to professional advice and efficient service, we were able to implement the solutions necessary for our company in time to serve the growing needs of our customers. In carrying out various tasks, HKK Group has become known as a professional contractor. We recommend HKK Group as a company rich in experience, yet modern, whose cooperation can be relied upon.

Supply chain optimization - bet on innovative solutions!

Optimizing your supply chain is essential to keep your operations running and deliver goods to your customers in the shortest possible time. Warehouse flows in particular are subject to identification, which you can support with modern technology. Crucial for efficient management is the use of an ERP system. We offer you a WMS system that is compatible with numerous devices, such as data collectors. The innovative software also allows you to manage orders and deliveries, supports the flow of logistical information and optimizes the execution time of individual tasks.

If you are wondering what is failing in your company’s logistics, the most common answer is an improperly designed supply chain. Optimization allows you to eliminate bottlenecks that lengthen processes, consume resources and generate high warehouse labor costs. Our specialists will help you find solutions to make supply optimization a reality, not just a possibility.

Trust HKK Group to automate your logistics processes

Optimization and productivity are key words in modern logistics. What can you invest in today?

Barcode readers, mobile terminals, label printers, industrial panel computers – these are just a selection of solutions for your business.

At HKK Group, we take an individual approach to each client, whether we are providing services to a multinational corporation or a local company. This allows us to offer you solutions that are precisely tailored to your needs. Using our support is an investment in what will realistically streamline your warehouse processes, optimize your supply chain and production processes.

Contact us today and see what we can do for you!

05/

Contact with us

Sulisław Słomski

Account Manager - Automation Solutions

Wojciech Stachowiak

Head of Automation Solutions Department

Maciej Szulc

Account Manager - Automation Solutions