Barcode scanner

Barcode scanner, QR code readers, 2D code reader. The devices commonly referred to as code scanners are those that can read barcodes or other data coding systems applied to a self-adhesive label or directly to a specific item (DPM-directed part marking).

Industrial readers

Barcode scanners, especially those used as handheld devices, come in two basic variants, depending on the degree of tightness and durability of their construction. Industrial scanners are ideal for heavy-duty industrial applications. Dust, moisture, or other adverse factors are no problem for them.

Handheld barcode scanners

Barcode readers can be used as handheld devices, allowing the user to read the code. This configuration of the reader, its compact size, the ability to adjust the reading distance (from a few centimeters to even a few meters) make the readers become an integral part of the logistics or production process.

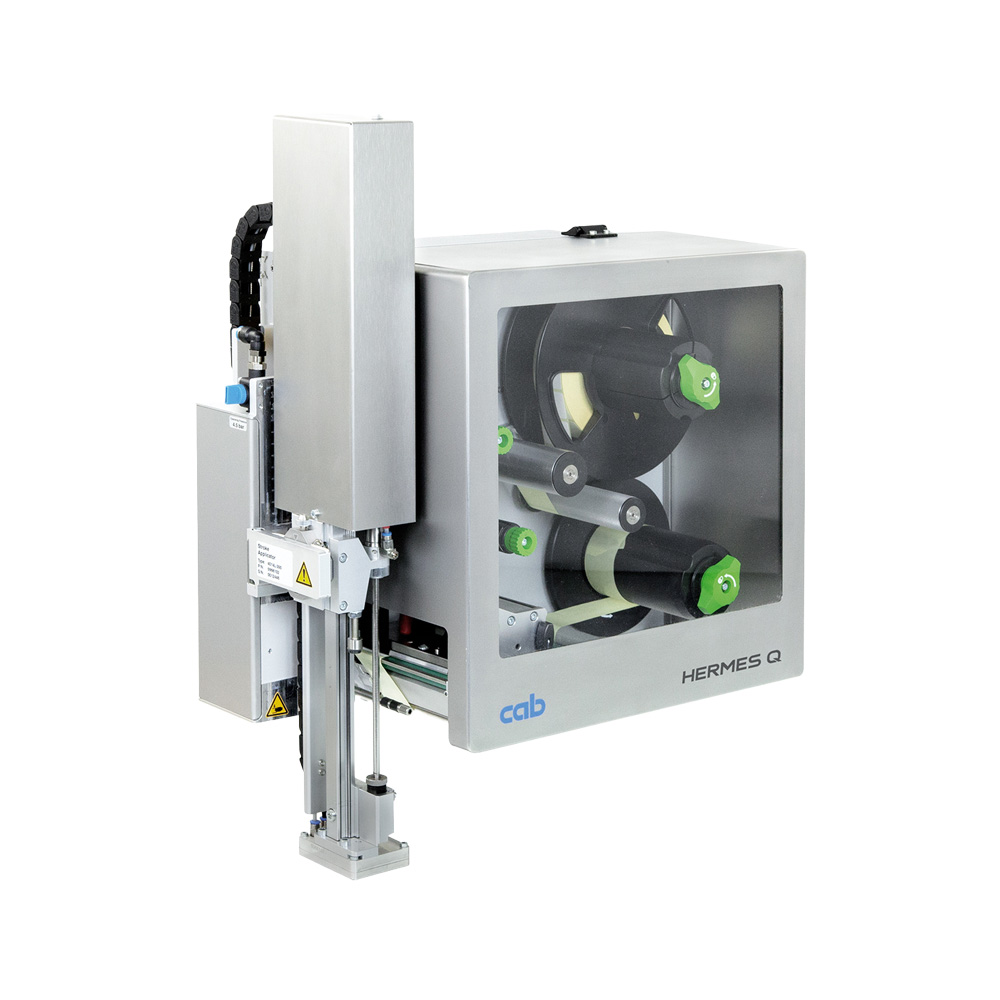

Automated barcode scanners

Automated readers are devices that are permanently mounted on the production line, at the cash register or at another process-relevant location, depending on business needs. Such devices automate the reading process, greatly increasing its efficiency.

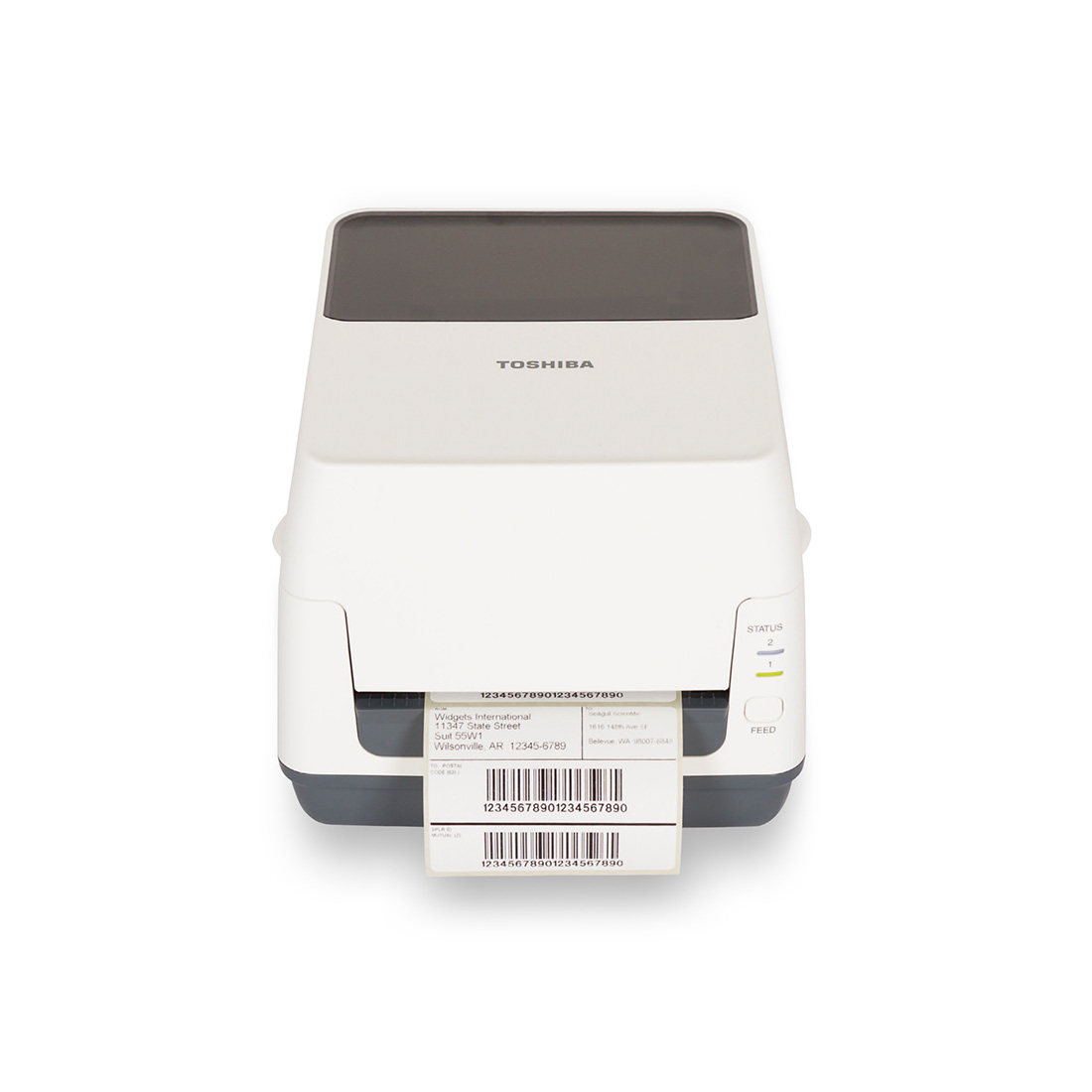

Barcode scanners

Barcode scanners typically operate with laser technology, allowing for fast and error-free reading. Such solutions are perfect for logistics or retail.

Vision scanners for 2D/QR codes

Modern business is increasingly moving to encoding in other systems (for example, 2D datamatrix codes, or QR codes). If such symbology is used, or if it is necessary to read the code from a mobile device, it is better to use imager readers. Such solutions provide the ability to read multiple codes simultaneously, and can feed information systems with data from codes and alphanumeric descriptions.

I highly recommend HKK Group (HIT-Kody Kreskowe) as a business partner. They are reliable, professional and always provide quality work. Their knowledge, attention to detail and awareness of our needs have been invaluable to our collaboration and I have no doubt that they will be a valuable asset to any team.

Alicja Kolendo

Head of Auto ID Devices Department