Key information:

Fast navigation

- The beginnings of identification in business

- Who invented the bar code?

- Types of barcodes – one-dimensional (1D) codes

- Types of barcodes – two-dimensional (2D) codes

- Why are certain sectors migrating to 2D standards?

- What are the primary benefits of 2D codes?

- Two-dimensional codes and benefits for supply chain participants.

- 2D codes – an itinerary, or what awaits us in the future?

- Different country, different code

- Barcode printing – in-house or outsourced?

- How to read the barcode?

- Barcode verification

- Barcodes mean greater efficiency for your organization

- Alternatives to barcodes: 2D codes and RFID

The beginnings of identification in business

The first tentative steps toward modernizing product identification were taken in 1932. At the time, Wallace Flint and a small group of students at Harvard University were trying to create a new solution for American stores. The idea was that customers would pull out a perforated card associated with a specific product. Such a card would then be inserted into a special reader, and the product would travel from the warehouse to the point of sale, where the consumer would receive a receipt after paying. The system was supposed to automatically make the necessary changes to the records, so that both the store staff and warehouse workers would know what is currently in stock and what has already been sold.

Who invented the bar code?

The idea was ambitious, but it was not until 1948 that we could talk about what we now know as the barcode. At the Drexel Institute of Technology in Philadelphia, a conversation took place between a local food entrepreneur and one of the university’s deans. Bernard Silver was fortunate enough to be near the speakers and shared the revelations he heard with Norman Joseph Woodland. At this point, research on the first barcodes began.

Initially, the inventors planned to use ultraviolet ink, but the idea was quickly abandoned due to the ink’s instability and excessive production costs. The first real barcodes resembled shooting targets (hence the name “bull’s eye barcodes”). Unfortunately, Silver and Woodland were not financially successful, despite the fact that their invention was quite advanced. The first bar code entered commercial use in 1966, four years after Silver’s death. Woodland was recognized by President Bush in 1992 with the National Medal of Technology.

Types of barcodes

One-dimensional (1D) codes

Today’s barcodes are very different from their ancestors. One-dimensional (1D) codes are the most common and widely recognized pattern for encoding information. These are the familiar dark and light bars that, arranged in a single line with appropriate spacing, carry specific information about the product.

Since some time has passed since the invention of the technology of encoding information in graphic form, we can find many different types of barcodes on the market. Over the years, however, certain standards have emerged that entrepreneurs around the world use to perform automatic identification. The most popular one-dimensional graphic symbologies include EAN-13, EAN-8, Code 39, Code 128, and ITF-14. Let us take a closer look at each of them:

EAN-13 and EAN-8

(European Article Number) – the EAN code family was created in 1977. . In commerce, we distinguish between the EAN-13 and EAN-8 versions. The “thirteen” consists of 12 data digits and one check digit, while the “eight” has 7 data digits and one check digit. The first 3 digits (GS1 prefix) indicate the country in which the product was registered (this is not equivalent to the country of origin of the good). EAN-13 is used on large-sized packages, while EAN-8 is better for smaller ones.

Code 39

Each character in this code consists of 9 bars (5 black and 4 white). Three bars are wider than the others, hence the name Code 39 (3 of 9). This code is attractive to the user because almost any barcode reader can read it. Due to its low data density, Code 39 is not recommended for small products.

Code 128

It consists of 11 black and white bars. The advantage of the code is the ability to place a large amount of information in a relatively small area. A subset of Code 128 is GS1-128, which is used in global transportation and product packaging.

ITF-14

Adaptation of Interleaved 2 of 5. It is used to encode the Global Trade Item Number. It consists of 14 decimal digits, and each digit consists of five bars. The distinctive black frame protects the entire code ITF-14 is usually used to mark bulk packaging.

Two-dimensional (2D) codes

Two-dimensional (2D) codes can also be found in circulation. In the case of these codes, two-dimensional images composed of black and white squares play the main role. All 2D codes have a huge advantage over traditional, one-dimensional codes – the ability to store much more information while maintaining a smaller size of the code itself.

Interestingly, unlike 1D codes, two-dimensional versions can also be used to record more complex graphics or even sound. Identification with some of the 2D codes is also mandated by major institutions (such as the traceability requirement in the tobacco industry imposed by the European Union).

We distinguish several two-dimensional codes based on their structure and use:

DataMatrix

A matrix barcode developed by International Data Matrix. DataMatrix uses square modules arranged within a search pattern. The great advantage of this type of code is that it can be scanned quickly and reliably, even if it is significantly damaged.

QR code

Developed in Japan in the 1990s . It is one of the best recognized 2D codes in the world and one of the most widely used in various industries. QR can encode characters from different alphabets, so it can be used in countries where the Latin alphabet is not used.

Aztec Code

A square field with a core (black dot) in the center, surrounded by a white border, which in turn is surrounded by a black border. The name is a reference to the temples.

2D codes are becoming increasingly popular-why are certain sectors migrating to 2D standards?

Consumers, retailers and others in the supply chain, expect even more opportunities to obtain information after scanning the code on a product. The classic bar code and especially the one-dimensional EAN 13 code, which is widely used in the retail sector, has one very important limitation. We are talking about the amount of data that can fit in such a code (in the case of EAN code 13 it is only 13 characters). Another major limitation of one-dimensional codes, is that they are far less readable with consumer-owned devices, such as a smartphone. These two factors will probably determine the future of barcodes and 2D codes in the retail sector.

What are the primary benefits of 2D codes?

Two-dimensional codes are a benefit to everyone in the supply chain

Two-dimensional codes in warehouses and distribution

- Support for lot/serial numbers in a single code: already at the stage of product marking by the manufacturer, lot and serial numbers can be assigned by putting it in a 2D code.

- Support for handling expiration dates: a two-dimensional code can have information about expiration dates, which in turn allows them to be better handled by a WMS-class warehouse management system.

- Product serial numbers: by using 2D codes, it becomes possible to handle serial numbers without generating additional labels. The serial number is a very important element for industries related to electronic devices or home appliances.

Two-dimensional codes in B2C and B2B circulation

- Support for traceability at every stage of the supply chain: the use of a two-dimensional code (whether in the Datamatrix standard or the QR Code standard) enables quick identification of product location, without the need for specialized hardware or software.

- Simplifying the registration/authentication process of the product which can have an impact on the satisfaction of its use.

- Simplifying the ability to recall a product by scanning a two-dimensional code.

- The integration of data on serial numbers, best-before dates, dimensions and much more increases transparency in the supply chain.

- Strengthen customer connectivity by integrating marketing tools with 2D code content.

Supporting a sustainable economy in the area of food production

- Reducing the amount of food wasted through better control of expiration dates.

- Increasing transparency in the supply chain, and consequently streamlining the distribution process with expiration dates.

- Better control of food quality and safety.

- Safeguarding against the influx of untested/dangerous food.

Two-dimensional codes - itinerary.

Supply chain participants, especially those associated with the retail sector, should expect big changes, and in the near future. GS1 and the Consumer Goods Forum recently announced an ambitious but feasible plan to transition to 2D codes (especially Datamatrix) in the retail sector as early as 2027.

This declaration has been followed by a number of initiatives by retail chains from many countries that are making a commitment to introduce the widespread use of 2D codes.

What does it take to use 2D codes? First and foremost, there is a need to change barcode reading devices to barcode and 2D code reading devices. It is about changing the code reading technology in code readers (code scanners) from laser to vision (imager). This is the right major change that will open the gates of global and widespread use for 2D codes.

What country is... code

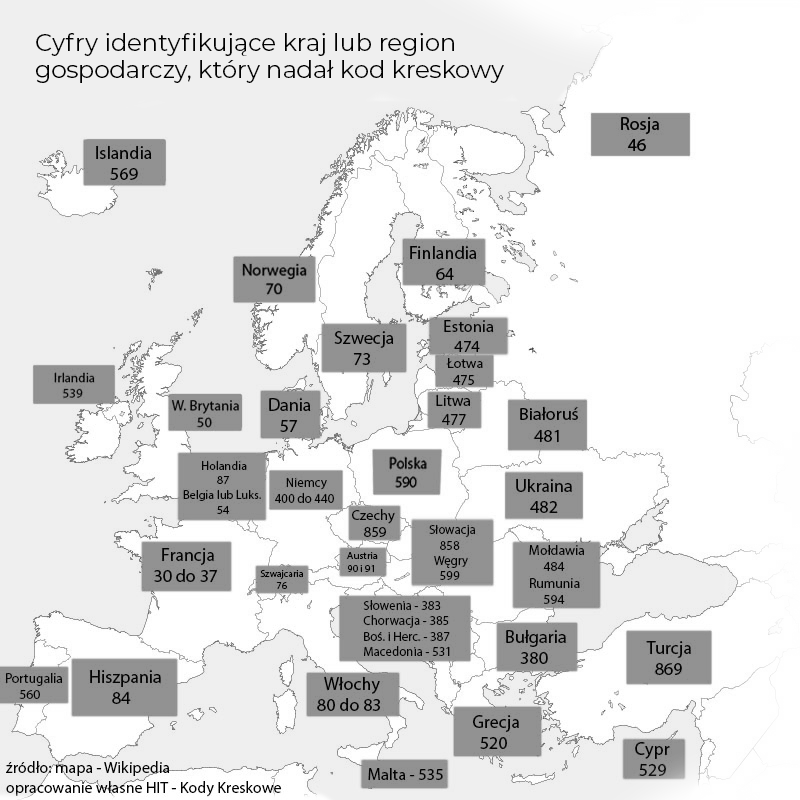

Have you ever wondered what barcode Poland has? According to global standards, each country is assigned a specific number that automatically identifies the country issuing a given barcode. The numbering system most often consists of two digits, less often of three. . Following this lead, Poland has the number 590, and e.g. Germany from 400 to 440. On the side there is a list of prefixes of European countries that issue codes.

Barcode printing – in-house or outsourced?

Companies can choose to create their own base and print barcodes themselves. This requires a label printer that prints codes on a specific material. It is also worth noting that such a solution usually works best when large volumes are not required. In the case of greater demand, we usually have to send an inquiry to a company that does wholesale printing professionally.

In some cases, we may need to report a given barcode to a higher authority to verify that it meets applicable standards. If an entrepreneur wants to produce codes for internal use only, it is not a problem for them to design, print, and use the barcodes on their own. Things start to get complicated when the company wants to ship products outside of its facility.

One such organization is GS1. It is the company that ensures the accuracy of barcodes and compliance with generally applicable standards. Many companies that print barcodes and all types of labels meet the criteria set forth by GS1. This means that products marked in this way can be safely shipped to any corner of the globe.

The material we print the code on is also an important consideration. Advanced facilities have access to printing technology and specialized materials All of this affects the reading of the barcode, since it is important for it to be readable and maintain appropriate parameters.

How to read the barcode?

Since almost every industry uses barcodes to identify products, you also need equipment that can read them. Barcode readers have been developed for this purpose. How do these devices work? A laser beam (or several beams) is emitted from the scanner and strikes the bar code. The laser is able to distinguish the distance between individual lines, as well as their color and size. The data recorded in the code is then visible to the barcode scanner, whose photodetector receives information about what it has seen and then sends it in the form of an electrical impulse to be displayed to the user.

However, there is a problem: conventional barcode readers cannot read two-dimensional codes. For this we will use the so-called imager. Imagers are nothing more than 2D code scanners that can also interpret information contained in 1D codes. The methods of reading data have been evolving together with the development of smartphones. Mobile phones with a good camera can be turned into portable barcode readers. Mobile terminals, which are multifunction devices that work well in many industries, also operate in a similar way.

It should be noted, however, that a phone with an app-based QR code scanner will not be sufficient if your business requires more products to be scanned. In this case, it is necessary to obtain specialized equipment capable of scanning in large quantities. This is what all kinds of vision solutions, mounted directly on the production line, are for.

Code verification

It is one thing to design, encode, and print a barcode, but it is also necessary to make sure that it is reliable and capable of conveying the information encoded. Barcode verifiers are used for this purpose. Users need readability to be sure that the code is read correctly. As we all know, time is money, especially when individual processes require quick and reliable reading of information contained on the product. Verifiers check products for accuracy and compliance with ISO standards. Verification can take place in-line, i.e. during the process. The alternative is to take samples from a series of printed barcodes and check them with a verifier.

Barcodes mean greater efficiency for your organization

Barcodes can significantly reduce the execution time of certain business processes, mainly by automating the data collection process. With barcodes, it is possible to track inventory in real-time mode, record production progress, or speed up inventory.

The following are areas that can be improved through the use of automatic identification techniques:

- Logistics sector: barcodes in logistics provide the technological basis for the operation of WMS-class warehouse management systems. Such systems cover the following areas: entry of goods into the warehouse, storage of goods in the warehouse, picking and preparation of goods for shipment.

- Manufacturing sector: barcodes in the manufacturing sector are used primarily for the ongoing control of the implementation of production processes. This happens through the use of barcode readers located on production lines, which read data on specific products manufactured on those very lines.

- Retail sector: barcode systems in the retail sector provide the opportunity to strictly control inventory and speed up the customer service process.

Alternatives to barcodes: 2D codes

An alternative to barcodes in business is the two-dimensional (2D) code. The big advantage of this form of coding, is the ability to increase security by limiting access to the information contained in the code, only to holders of a special key, which can be accessed only by defined individuals.

The use of 2D codes in business has been going on for more than a dozen years, and some of the biggest successes include the spread of this form of coding in the process of packaging medicines, or other strictly stock products. Some countries have a closed coding system for alcohol products, whereby 2D codes printed on bottles are assigned by tax authorities during the packaging process. This is made possible by the integration of the packaging system with the code generation system maintained by the relevant state authorities.

RFID.

RFID technology is a modern contactless identification technique. With this identification method, RFID tags equipped with an antenna and a memory element containing a unique identifier communicate with the antenna and RFID reader.

Such communication can take place passively-the tag is excited by a signal from the reader or actively-the tag itself communicates with the reader). Readings can be taken from as far as several meters and multiple tags can be read simultaneously.