Key information:

If you want to improve your chances in a highly competitive market, you should do everything you can to ensure that your products get into the hands of your customers on time, at the lowest price and in the form they most expect. In this article you will find some tips whose implementation will make your warehouse work even better.

Digital warehouse - WMS supports supply chain

The absolute basis for considering the digitization of the warehouse, is a functional WMS (Warehouse Management System), or warehouse management system. It covers with its supervision the basic warehouse processes, from the moment the goods enter the warehouse, through storage and release.

The operation of the WMS class system is supported by barcode technology, although these are increasingly being replaced by two-dimensional datamatrix codes, as well as wireless RFID technology. Each of these technologies provides instant identification of goods, warehouse zones and better preparation of shipments.

Implementing a properly configured WMS that takes into account all elements of the warehouse workflow (organizing them in the most intuitive way possible), reduces the number of mistakes proper to zero, speeds up warehouse operation by up to 30%, and supports the use of warehouse automation elements.

Controlling the entry and exit of the warehouse (inbound & outbound logistics)

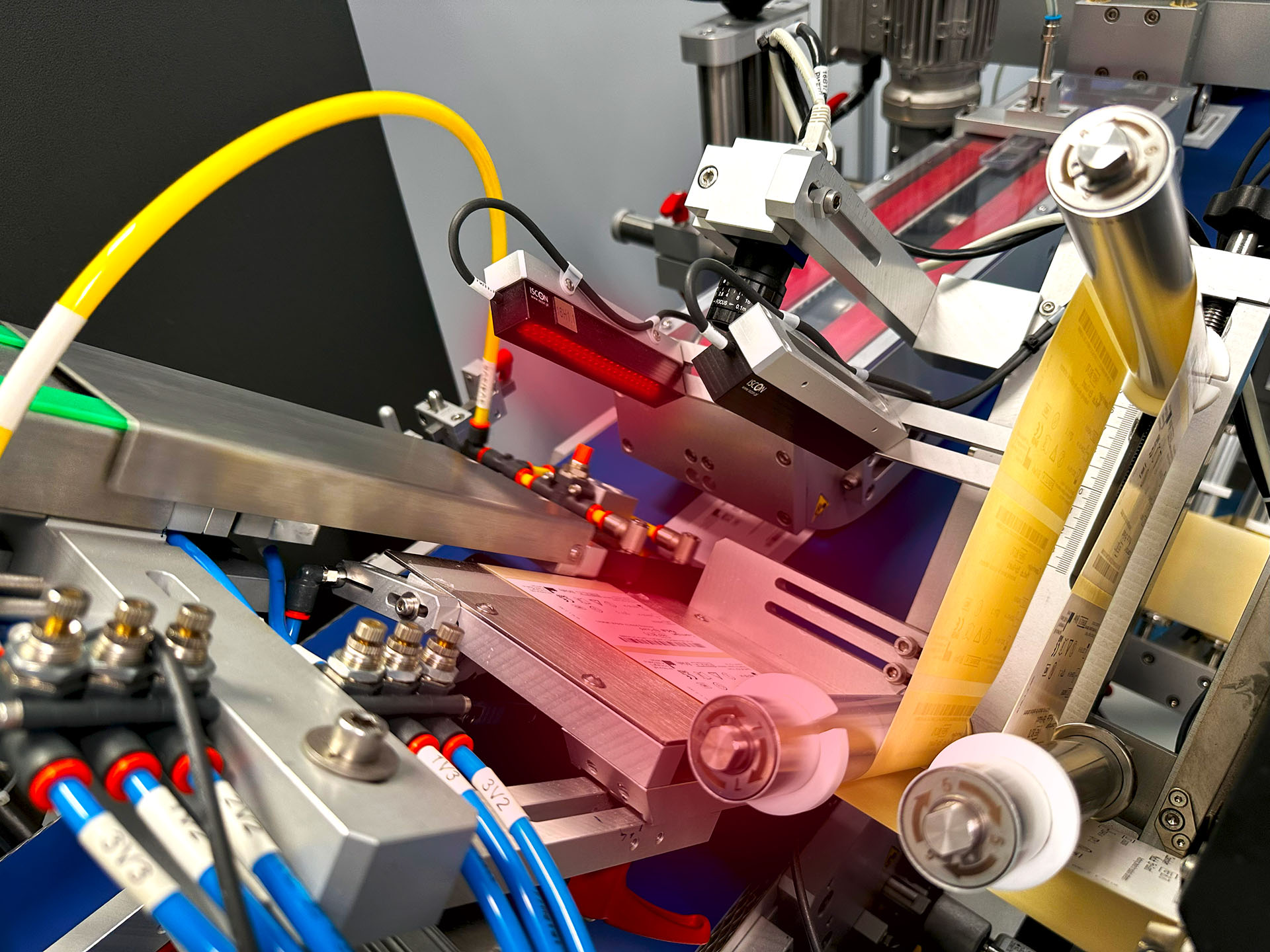

Can you imagine automating the process of receiving or releasing goods, which would result in not having to manually scan each pallet or package? This is possible by implementing a system of scanning gates that will automatically read the contents of the label placed on the package.

Interestingly, label reading is also possible for pallets filled with multiple products that have their own product label. Thanks to the use of machine vision technology, scanning gates, in addition to reading the code, can also analyze the image of the packaging or the product itself to determine its damage, incompleteness, etc.

Digital robot eye

Vision systems also support the increasingly common area of robotization. Whether we’re talking about automated guided vehicles (AGVs) or robotic handlers used, for example, in the palletizing process, it is the vision system is responsible for finding a particular area, orienting in space, or finding a particular package or product.

Vision systems not only increase the efficiency of daily warehouse operations, but also enhance safety at the distribution center.

Vision systems not only increase the efficiency of daily warehouse operations, but also enhance safety at the distribution center. It's an investment with a fast rate of return.

Vision-based product dimension analysis means improved product data quality and better shipping efficiency

The quality of master data in logistics management systems is very important both from the perspective of intra-warehouse processes and from the perspective of the transportation and delivery process. Master data (i.e. the aforementioned master data), is the most important information about a specific product index (SKU), such as dimensions, weight or packaging method. The quality of this data has a very strong impact on the effective management of warehouse resources such as:

- Storage space – precise product sizing allows for more efficient use of racking space, thus accommodating more products using the same warehouse space).

- Packaging optimization – Precise dimensioning of the product allows you to choose the optimal packaging. After all, nobody wants to transport air!

- Realistic data for carriers – master data, is not only product data, but also precise data on the dimensions of shipping packages. Being at the disposal of such data, we can better price the cost of transport services and avoid costly surcharges for excess dimensions of packages, relative to the declared dimension.