Information system for production, the nucleus of the management of a modern plant.

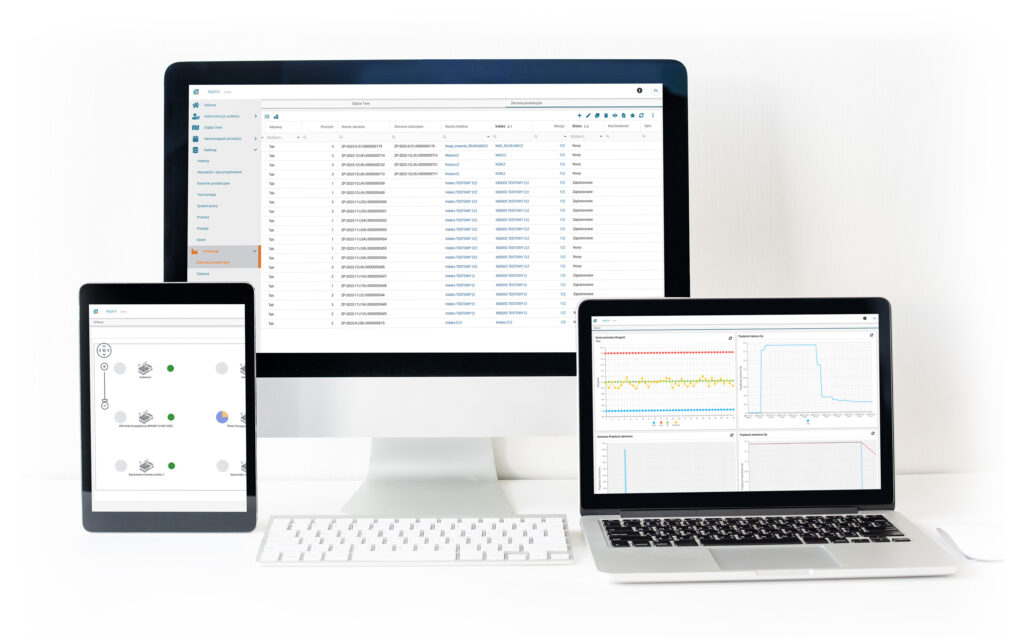

The most important element related to the functioning of manufacturing companies in the future, will be an efficient and intuitive information system to support decision-making processes in the area of production planning. A good example is the system designed by our company together with Poznan University of Technology DigitIO Factory. It is a complete tool enabling:

- Production planning based on predefined technologies.

- Control of warehouse logistics (also in conjunction with our WMS).

- Constant and ongoing supervision of production processes directly on the shop floor – MES functionality (through the use of sensors, user interfaces and Internet of Things elements).

Decision support

An element that significantly affects the optimization of production planning is the decision support module. It provides the opportunity to analyze alternative scenarios that are implemented in the digital twin (digital reflection of production).

The scenario that guarantees the achievement of results closest to the target will be the scenario that will be used in the real production plan.

A good example of an IT system for production management is the DigitIO Factory system, designed by our company together with Poznan University of Technology.

Machine Vision - using vision technology to control processes.

A technology that is gaining more and more adherents in the field of digitizing production processes is the so-called “digital production”. machnine vision, or digital image analysis technology. Our company specializes in developing systems for analyzing events directly on the production line. These can be elements that allow the reading and analysis of specific production parameters, or systems that give the possibility to control the quality of manufactured products directly during their production.

Machine vision systems can also assist in the serialization of production, in which case they will only be one component of such a system. Vision systems also support automatic identification based on a barcode or two-dimensional code (for example, the increasingly popular data matrix code).

Robots are increasingly replacing human labor-how to streamline repetitive processes.

The presence of robots on the shop floor is not new. It is the manufacturing sector that has pioneered the use of such solutions to speed up and reduce the cost of executing repetitive processes. A sort of novelty, however, is the significant reduction in the cost of entry into robotics systems.

Production robots do not have to perform highly complex tasks. Our offer includes robots that will successfully take over the task of marking products or pallets after production is completed (print&apply type systems). There are also robots for transporting components directly to production nests (autonomous vehicles) and so-called cobots that perform simple tasks such as preparing pallets with goods after production.

Each robot should, of course, be integrated with the IT system that manages the production process and possibly with the WMS.

A breakthrough in contactless identification technology - RFID in manufacturing.

Continuing to consider the manufacturing of the future, RFID identification technology is also worth mentioning. This technology has already been working successfully for years in the manufacturing industry, especially in the automotive sector.

Continuous development of RFID infrastructure has made the possibilities of its application much wider. With RFID, it is possible to control individual production processes by identifying manufactured items in a contactless way – using radio waves.

It is also a technology that offers tremendous opportunities in the area of closed-loop control of production packaging flow, or Control of the tasks performed under the so-called “control”. production logistics (just-in-time deliveries, production outlet service, etc.).

HKK Group - Your partner in preparing today's manufacturing for the future.

For years, our company has successfully implemented technological solutions to prepare our clients to meet the changing economic environment.

Our philosophy is to be a so-called “One Stop Shop” for manufacturing and logistics companies. It is by acting in accordance with this philosophy that our clients’ technological development is always one step ahead of the competition chasing them.