Gradual investment in automation

Replacing simple, repetitive manual work with automation elements is undoubtedly the future of the modern warehouse world. Investing in automation, however, can be incremental.

This approach seems to make the most sense for organizations that are just beginning their journey with digital storage, and this type of business is the majority in our country.

When considering initial investments, it is worth choosing areas where it will be possible to replace the work of operators with machines at little cost. One such area is definitely logistics.

WMS - the key to warehouse automation

Logistics and manufacturing automation must be based on robust software. In the case of a warehouse, such a foundation is a WMS (warehouse management system). This type of solution manages the entire warehouse operations, from receipt of goods, through storage, to the process of picking and releasing goods to the customer.

The basis for the operation of a WMS is automatic data identification equipment, such as label printers, data collectors, barcode scanners (code readers), using proven and stable barcode technology. It is thanks to these solutions that the time needed to identify goods in the warehouse is reduced, and mistakes in the process of order picking and shipping itself are minimized.

In the picking process, the ordered goods are taken from a defined and system-assigned location in the warehouse. In the next step, the goods are repacked into shipping packages and then released for shipment. It is this area that can be automated at a relatively low cost.

Automatic labeling after picking - self-adhesive label on carton

In the case of shipping goods of smaller dimensions, the repackaging process involves placing them in cartons or shipping bags. This type of solution carries great optimization potential, by adjusting the size of the packaging to the actual size of the product, which can consequently lead to a reduction in shipping costs and increased subjective customer satisfaction with the product received.

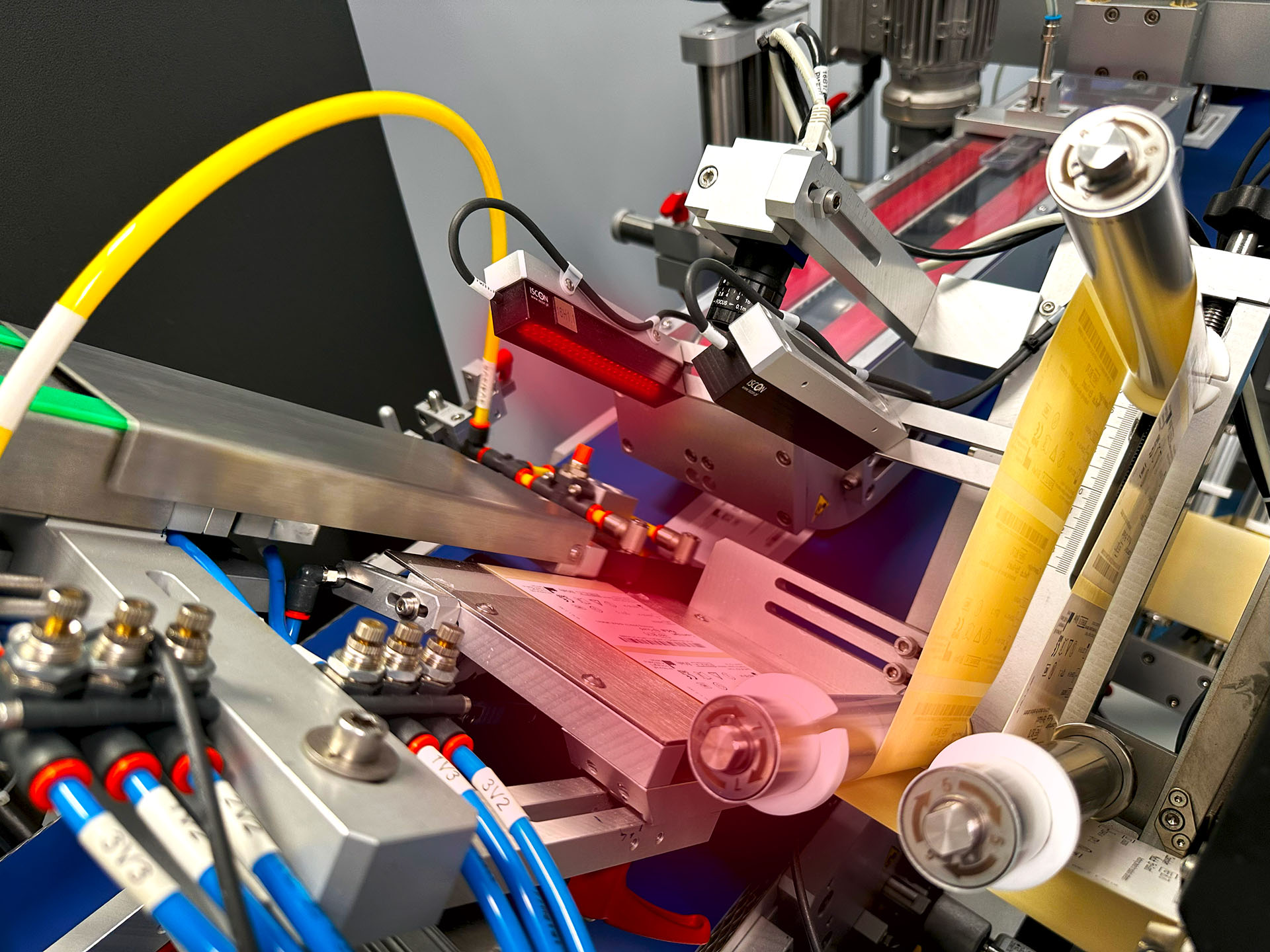

Another element that has optimization potential in the context of smaller packages is the ability to automate the labeling of shipping packages through the use of PRINT&APPLY systems . Such systems are integrated with WMS solutions, which in turn are integrated with courier systems.

As a result, each shipment to be shipped is labeled in an automated manner, which significantly speeds up release operations and reduces their costs.

Labeling of full-pallet shipments

For warehouses handling shipments of larger goods or distribution centers handling B2B relationships, full-pallet shipping is a more reasonable form of shipping.

PRINT&APPLY solutions are perfect for applying pallet labels to the front, side or front and side of a pallet.

Machine vision - vision-based quality control

Solutions of this type can be combined with machine vision systems that check the contents of a pallet and verify its dimensions and weight before starting the labeling process, which, after approval in the WMS system, generates the content of the transport label, which is finally applied to the pallet.