Key information:

Improved quality of master data.

CUBISCAN ‘s dimensioning solutions are first and foremost tools that dramatically improve the quality of master data on products that are stored in the warehouse. One of themaster data elements(master data) is information about the weight and dimensions of products. Such data affects the following areas of warehouse operations:

- Optimize storage in the warehouse: precise dimensional data allows better management of storage locations in the warehouse, making better use of available space. It is estimated that the space gain by optimally adjusting the storage space to the dimensions of the products can be up to several percent.

- Optimal shaping of the picking process: optimizing picking and subsequent repacking allows you to create picking lists that will take into account the dimensions and weight of the products being picked, so you can build packages with the right order of products to prevent damage.

- Optimizing shipping packaging: dimensioning in logistics supports the optimal selection of shipping packaging, adjusting it to the dimensions of the products being shipped, thus reducing last-mile logistics costs. Precise dimensions become the basis for calculating the real cost of shipments, without the need for surcharges in the future.

How is product sizing done?

The dimensioning process itself depends on the nature of the items we are dimensioning. Cubiscan offers solutions for dimensioning products with regular and irregular shapes, as well as solutions for dimensioning pallets.

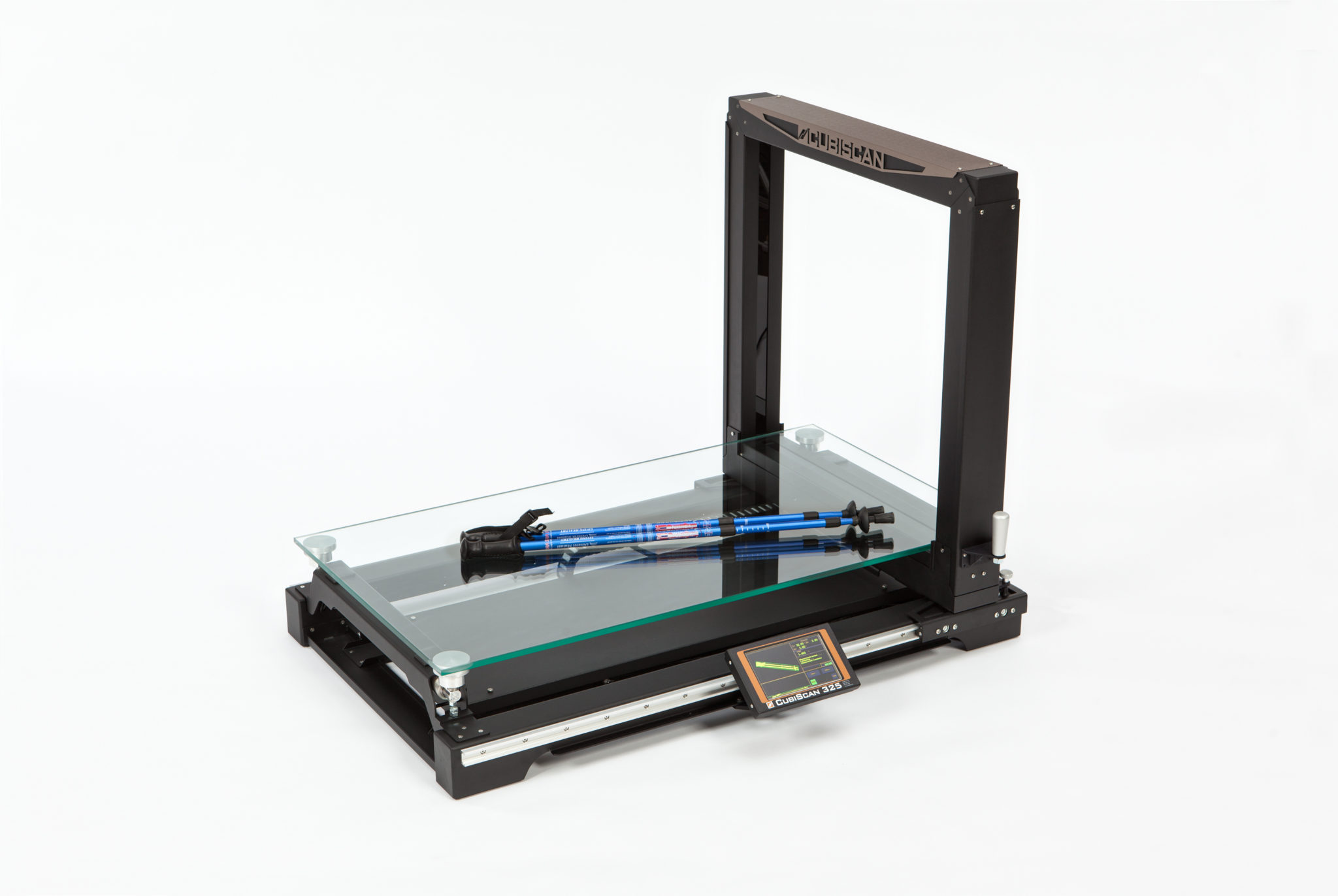

When sizing products, the Cubiscan system (for example, Cubiscan 325) is combined with a barcode reader to quickly read the barcode from the product. Automatic sizing is then carried out, and the data is sent in real-time to a host system (for example, a WMS).

In the case of pallet dimensioning, the dimensioning takes place when the pallet is set aside for dimensioning, and once the dimensioning is completed, the pallet can be additionally wrapped in plastic and labeled in preparation for shipping (the dimensioning process itself can, of course, take place after the pallet is already wrapped in plastic).

For both products and pallets, the dimensioning process is automated and takes seconds, and the result is very precise and can be automatically loaded into any external system.