Stationary medium range industrial scanners

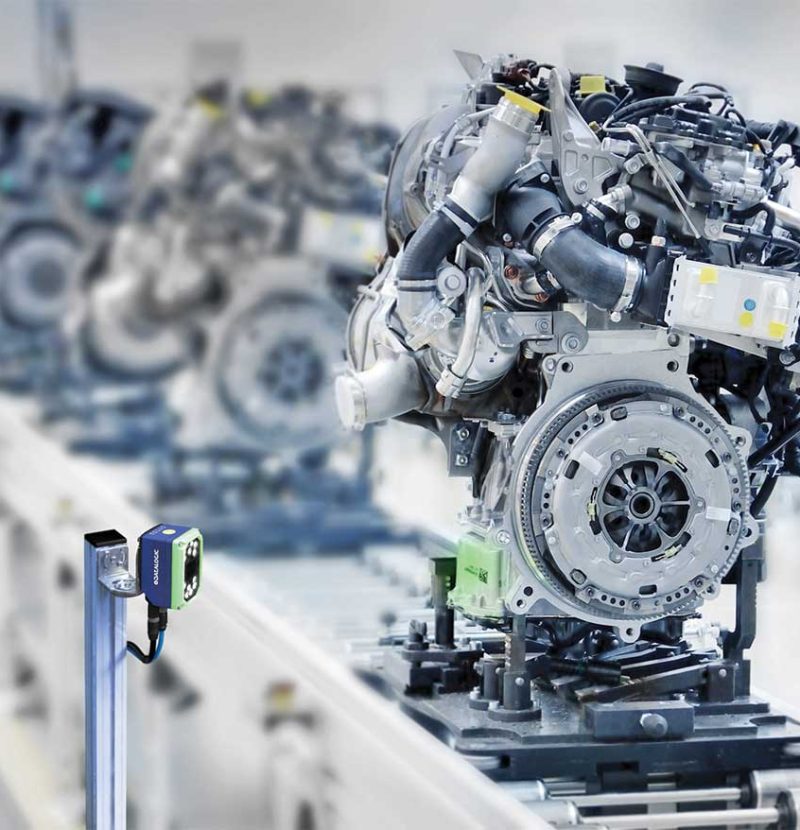

Advanced industrial mid-range scanners are designed for high-speed production lines and applications with difficult markings. They are the foundation of traceability, DPM reading and OCR systems in modern manufacturing and logistics environments.

Zebra FS40 | Zebra FS42 | Zebra FS70 | Datalogic Matrix 320

01/

Industrial code scanners - OCR, DPM, traceability

Mid-range industrial scanners are solutions designed for the most demanding manufacturing and logistics applications, where high reading performance, resistance to variable mark quality and the ability to perform functions such as DPM, OCR and full traceability are crucial.

The devices in this class offer high resolution, high processing power, and extensive optics and illumination systems. They enable stable reading of multiple codes at the same time, operation at high line speeds, and support difficult markings such as microcodes, codes marked directly on parts (DPM), and text and alphanumeric characters (OCR).

These scanners communicate directly with industrial automation and IT systems such as WMS, MES and quality control systems, operating continuously 24/7. They are a key component of modern Industry 4.0 systems, where code reading is an integral part of process control and product traceability.

02/

Application of industrial code scanners

Advanced industrial scanners are used where compact desktop scanners no longer provide sufficient performance, flexibility or reading efficiency.

The most common application areas include:

- Production and assembly lines – identification of components, semi-finished and finished products

- Traceability and WIP – linking product to batch number, date, work slot and operation

- DPM reading – laser, needle or chemical marked codes on metal, plastic and PCBs

- OCR and print verification – reading serial numbers, dates, batches and alphanumeric markings

- Packaging and quality control – verification of labels, completeness and correctness of markings

- Intralogistics – identification of cartons, containers, trays and transport carriers

- Machine automation and OEM – integration in machines, process lines and special stations

Thanks to their high computing power, these scanners can perform advanced scenarios such as ManyCode, OCR supported by AI algorithms, reference image comparison, diagnostic image storage, and full integration with PLC, WMS, MES and quality control systems.

These are key elements of modern factories, where scanning is an integral part of process automation.

03/

Devices available in our offer

Zebra FS40/FS42

- industrial communications: Ethernet (PROFINET, EtherNet/IP, Modbus TCP), USB-C

- 2.3 MP or 5.1 MP resolution (depending on version)

- reading 1D / 2D / DPM codes

- Up to 60 fps, Zebra PRZM imaging technology, ImagePerfect+, ManyCode

- automatic image configuration (Auto-Tune)

- integrated lighting, SR and WA optics versions

- Industrial-grade metal housing, IP65 / IP67

- digital inputs/outputs for automation integration

- Zebra Aurora platform – configuration, diagnostics and feature expansion

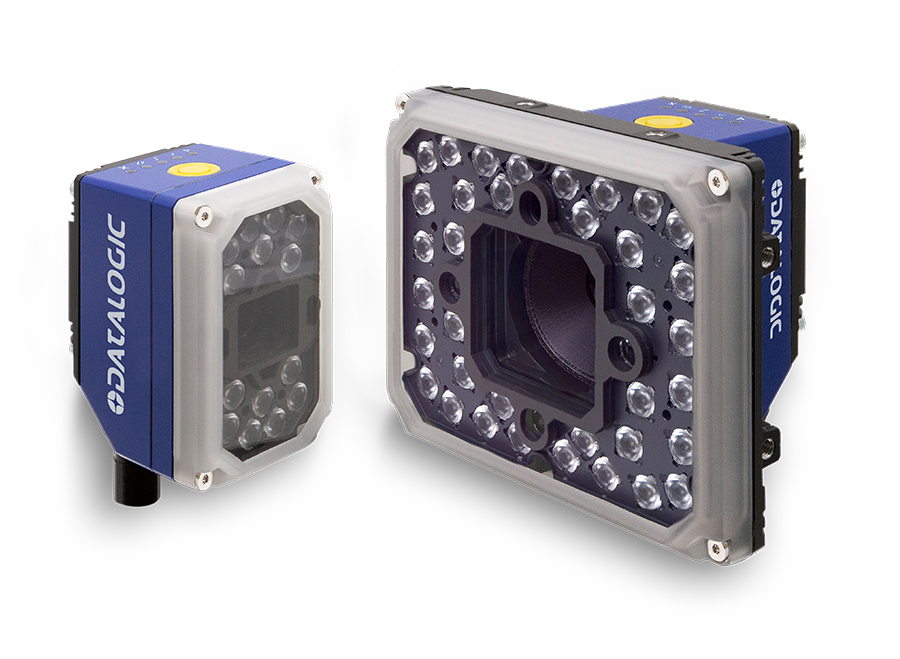

Datalogic Matrix 320

- Ethernet, PROFINET, EtherNet/IP, Modbus TCP, OPC UA, PoE communication

- reading 1D / 2D / DPM codes

- 1.2 MP sensor, electronic focus adjustment

- advanced lighting (white, red, blue, DPM, polarization)

- Digimarc, HDR and difficult surface support

- inputs/outputs and ESD versions

- metal housing, IP65 / IP67

- different versions – number of diodes / size

Zebra FS70

- Ethernet, USB or RS-232 communication (depending on version)

- reading 1D / 2D / DPM codes

- WVGA or 1.2 MP sensors

- wide selection of optical versions (standard, wide, polarized)

- ESD versions available for electronics

- very compact housing, IP65

- DL.CODE configuration and quick startup