AMR autonomous mobile robots

Automate your internal logistics with the help of AMR GoPal robots. Save time and money with reliable, flexible solutions that you implement without revolutionizing your infrastructure.

01/

Automation of warehouse logistics

Automated internal logistics has never been so simple and cost-effective

GoPal’s solutions make it possible to automatically lift, transport and deliver pallets and components without the need for a major infrastructure overhaul. AMR robots operate 24/7/365, ensuring process continuity, cost savings and improved safety in warehouses, manufacturing plants and distribution centers.

With GoPal’s flexible configuration, you can handle both simple A-B routes and more complex production processes. GoControl FMS enables full fleet management and integration with WMS, ERP and open API systems. Implementation doesn’t require major changes – it only takes a few weeks to get the system working for your return on investment, which happens quickly – usually in as little as 6-18 months.

02/

Why invest in robotization?

Robotization of logistics is an investment that pays for itself quickly - often within 6-18 months.

When you choose GoPal, a solution from our Danish partner Robotize, you not only gain reliability and safety, but also local technical and training support. Cheaper alternatives often end up with downtime and costly service. GoPal simply works – stably, predictably and seamlessly.

What do you gain from GoPal?

Minimize human error and damage to goods

Unburden the team and redirect employees to higher value tasks

Scalability and easy system expansion

Enhanced work safety

Reduction of operating costs

Ability to analyze data and continuously improve processes

Local support

Trouble-free operation

Quick return on investment

03/

Robotize autonomous warehouse robots

GoPal E22

The GoPal E22 autonomous mobile robot is designed to transport low- to medium-weight cargo (up to 500 kg) on europallets or half-pallets.

- Dimensions (L x W x H): 1400 x 860 x 340 mm

- Operating time (autonomy): 6-14 hours (or up to 20 km)*.

- Maximum speed: 2.4 m/s (8.6 km/h)*.

- Maximum load capacity: 500 kg

GoPal E24

Although visually similar to the GoPal E22 model, the GoPal E24 autonomous mobile robot has “bigger muscles” and is designed to transport heavier loads – up to 1,000 kg – on europallets, half-pallets or similar carriers.

- Dimensions (L x W x H): 1400 x 860 x 340 mm

- Operating time (autonomy): 6-14 hours (or up to 20 km)*.

- Maximum speed: 2.4 m/s (8.6 km/h)*.

- Maximum load capacity: 1000 kg

GoPal E24W

The GoPal E24W is an autonomous mobile robot designed to transport wide and very heavy loads (up to 1,200 kg) on industrial Euro pallets, standard Euro pallets, half pallets or similar pallets and cages.

- Dimensions (L x W x H): 1400 x 860 x 340 mm

- Operating time (autonomy): 6-14 hours (or up to 20 km)*.

- Maximum speed: 2.2 m/s (7.9 km/h)

- Maximum load capacity: 1200 kg

GoPal U22W

The GoPal U22W autonomous mobile robot is designed to transport low- to medium-weight cargo (up to 500 kg) on UK/US type pallets.

- Dimensions (L x W x H): 1400 x 1060 x 340 mm

- Operating time (autonomy): 6-14 hours (or up to 20 km)*.

- Maximum speed: 2.2 m/s (7.9 km/h)

- Maximum load capacity: 500 kg

GoPal U24W

The GoPal U24W autonomous mobile robot is designed to transport medium to heavy loads (up to 1,200 kg) on UK/US type pallets.

- Dimensions (L x W x H): 1400 x 1060 x 340 mm

- Operating time (autonomy): 6-14 hours (or up to 20 km)*.

- Maximum speed: 2.2 m/s (7.9 km/h)

- Maximum load capacity: 1200 kg

GoPal P35

The GoPal P35 autonomous mobile platform is designed to transport carts, cages, conveyors and similar carriers weighing up to 250 kg.

- Dimensions (L x W x H): 960 x 660 x 295 mm

- Operating time (autonomy): 8-14 hours (or up to 20 km)*.

- Maximum speed: 2.4 m/s (8.6 km/h)

- Maximum load capacity: 250 kg

04/

GoControl FMS Software

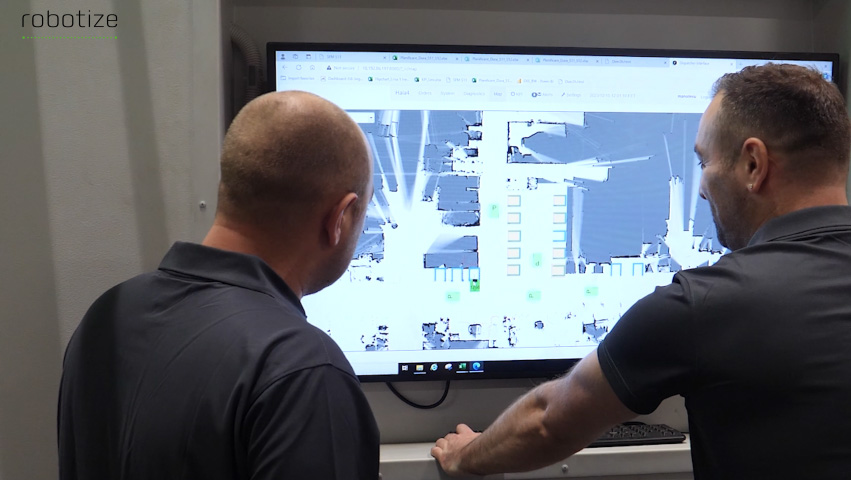

GoControl® - fleet management system for autonomous robots

GoControl Fleet Management System (FMS) is a web-based application that manages the entire ecosystem of GoPal solutions – from job queuing to system component status to real-time robot tracking and much, much more.

The system provides full control over material flow and optimizes the use of robots in the enterprise. With a clear interface, operators can easily supervise the operation of the entire fleet, diagnose problems and manage tasks in real time.

GoControl also supports integration with external systems (e.g., ERP/WMS), allowing for even more automated and seamless logistics processes.

05/

GoPal accessories and components

To realize the full potential of GoPal robots, we offer a wide range of accessories to facilitate integration into manufacturing and logistics processes.

Some of the solutions available include.

- Lifting stations (mobile or columns) that automatically adjust the height of pallets to match a specific process step.

- Conveyor stations (conveyor stations) allow direct transfer of loads between the robot and the production line.

- Modular pallet stations make optimal use of space thanks to the pallet indexing function.

- The system is complemented by call buttons, pallet sensors, traffic lights and other devices that enhance automation, security and control of the entire GoPal fleet.

GoPal’s accessories make it easy to adapt the system to existing layouts of production halls and warehouses, without the need for a major infrastructure overhaul.

With their modular design and readiness to integrate with ERP, MES or WMS systems, these accessories support scalability and operational continuity – regardless of industry.

It’s an investment in flexibility, safety and efficiency that allows you to fully automate your material flow and prepare your plant for the future.

Modern AMR robots are a solution that streamlines logistics processes, increases safety and reduces operational costs. Using autonomous navigation technology, autonomous mobile robots (AMRs) independently plan routes and carry out transportation tasks without human supervision.

Why choose AMR mobile robots?

Every HKK Group-branded mobile robot available works by intelligently mapping the space, eliminating the need for markers or guide rails. The device detects obstacles and safely avoids people and equipment. The use of transport robots reduces internal delivery times and the risk of errors. It’s a solution that combines efficiency with complete user safety.

Flexible and scalable transportation robots

Systems based on AMR mobile robots can be easily adapted to the specifics of any warehouse or manufacturing plant. Their modular design allows quick adaptation to new processes or changes in the layout of the hall. Autonomous mobile AMR robots cooperate with WMS and ERP systems, automatically downloading data on transport tasks. This guarantees smooth operation and full control over material flow.

Read more

Save time and costs with autonomous mobile robots (AMR)

AMR robots eliminate the need to transport loads manually, significantly increasing the efficiency of operations. The transport robot can operate around the clock, charge built-in batteries automatically and perform repetitive tasks with the utmost precision. The reduction in forklifts and manual labor translates directly into lower infrastructure maintenance costs and reduced risk of accidents.

Intelligent AMR – robots of the future

Modern autonomous mobile robots (AMRs) from Robotize use artificial intelligence and advanced navigation algorithms. They analyze the environment in real time, react to changes and optimize travel routes. AMR mobile robots can avoid collisions, avoid obstacles and operate in a dynamic warehouse environment without supervision. It’s a technology that guarantees stability and process continuity.

Benefits of deploying AMR autonomous mobile robots

Investing in AMR mobile robots from HKK Group is a decision that brings a quick return and long-term benefits for the entire organization. By implementing them, you gain full control over internal transportation and optimize logistics processes.

Key benefits provided by autonomous mobile robots (AMR):

- Reducing transportation and internal handling costs,

- Better organization of work through automation of repetitive tasks,

- Increasing worker safety and eliminating human error,

- Uninterrupted operation of the system 24/7 without the need for supervision,

- Quickly scale and flexibly adapt to the needs of the plant,

- Minimal infrastructure requirements and simple implementation.

Deploying autonomous mobile robots (AMR) does not require costly shop-floor remodeling – all you need is a system setup and a short training session for operators to get started. With us, you gain technology that realistically improves logistics, speeds up processes and allows you to achieve more with less time and resources.

Get a head start with HKK Group

Bet on proven autonomous mobile robots (AMR) and automate transportation in your company. Contact us to learn how AMR robots can increase the efficiency, safety and profitability of your processes. Digitization of business processes and implementing robotics is a must for any company that wants to stay competitive!

05/

Contact with us

Sulisław Słomski

Account Manager - Automation Solutions

Wojciech Stachowiak

Head of Automation Solutions Department

Maciej Szulc

Account Manager - Automation Solutions