Automation for logistics

In a world of rising labor costs and constant shortages of qualified personnel, it is necessary to look for solutions that automate warehouse logistics processes. In order to properly identify the potential for automation, look for task repetition. If work in a particular area is repetitive, it is likely that it can be automated.

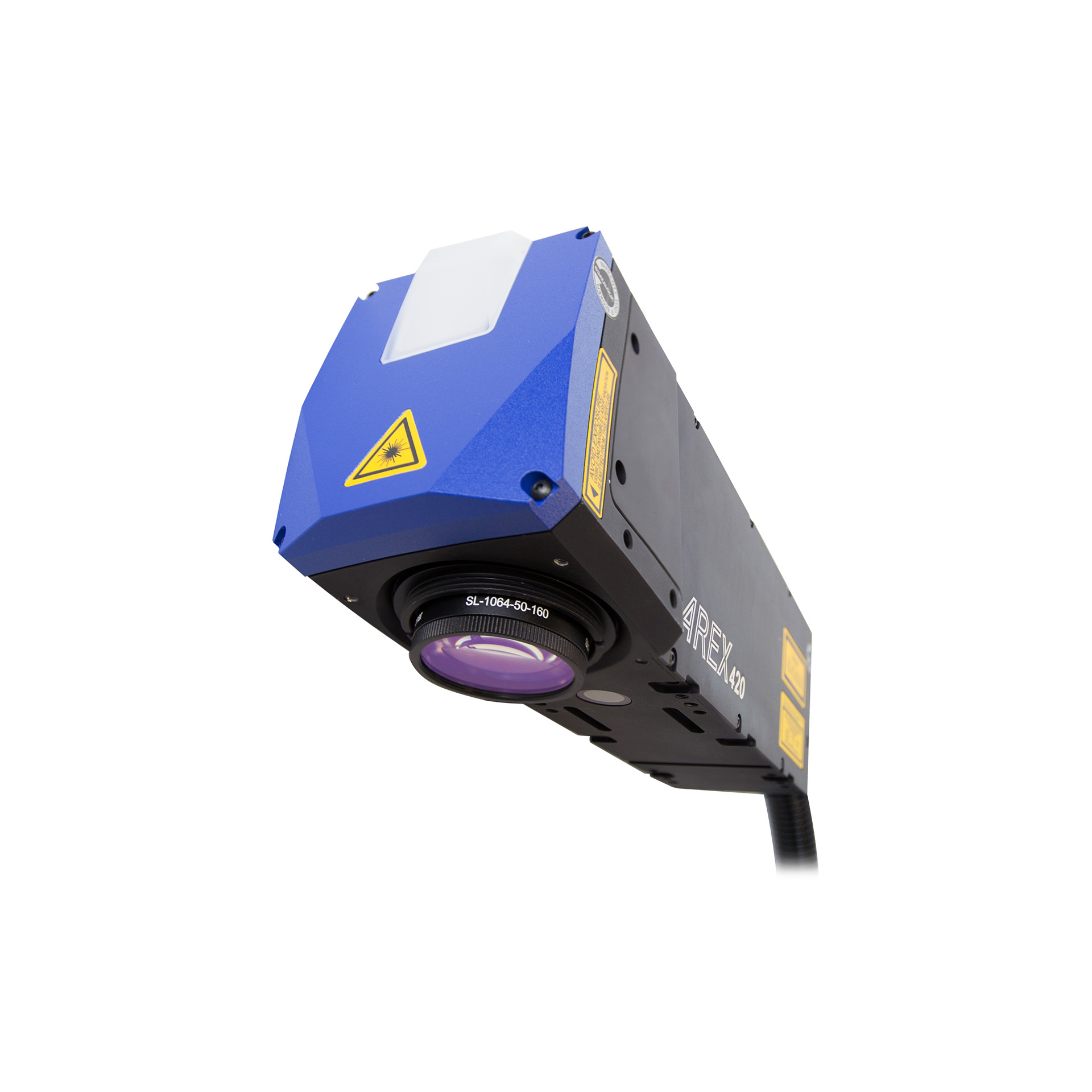

Integration on transportation/production lines

Solutions that automate the reading of barcodes on lines, just like devices that automate “on the fly” dimensioning or visual quality control systems, very often need to be integrated with transportation lines. Our specialists have the competence and experience to integrate any device with any line using controllers from leading industrial automation suppliers.

Print&Apply Systems

An important part of the work in a modern warehouse is the labeling of goods and pallets. Labels are used both when receiving goods to the warehouse (printing registration labels in the WMS) and when preparing goods for shipment. Our specialists support the process of printing and applying adhesive labels by constructing print&apply devices, i.e. automatic labeling machines for labeling pallets, boxes, or bottles.

Logistics robots

HKK, together with renowned Partners, also offers logistic robots that improve internal transportation or picking processes. These solutions are especially recommended for warehouses performing tasks related to e-commerce, where they perfectly complement the operation of WMS solutions (e.g., by accelerating the picking process based on a multi-order picking strategy).

Thanks to professional advice and efficient service, we were able to implement the solutions necessary for our company in time to serve the growing needs of our customers. In carrying out various tasks, HKK Group has become known as a professional contractor. We recommend HKK Group as a company rich in experience, yet modern, whose cooperation can be relied upon.

Wojciech Stachowiak

Head of Automation Department

Artur Mumot

Senior Account Manager - Print&Verification