Print and Apply

CAB label applicators are state-of-the-art devices designed to automatically apply labels to products, packaging or components in a variety of industries. Unlike traditional label printers, which require manual operation, CAB applicators integrate the printing and application process in one continuous cycle, significantly increasing efficiency and repeatability.

01/

Printer and label applicator for modern manufacturing

Traditional industrial printers, even the most advanced ones, require manual label application. For many companies, this is no longer enough. More and more companies are reaching for integrated 2-in-1 solutions – devices that print and automatically apply labels without operator intervention. This saves time, costs and increases productivity.

How does the label applicator work?

The automatic label applicator is a system that combines the function of printing with immediate application on a product, carton or pallet. The entire process takes place in real time and does not require the intervention of an employee. Such a solution is perfectly in line with the direction of development of modern plants – full automation of processes.

Where will automatic applicators perform well?

Integrated print and application systems are a solution for companies that focus on efficiency and precision. They will prove themselves in, among other things:

warehouses and logistics centers,

manufacturing plants,

Pharmaceutical, cosmetic and food industries.

Modern applicators can handle a variety of product shapes – from cardboard boxes to semicircular packaging and delicate glassware.

02/

CAB solutions offered by HKK Group

At HKK Group, we offer CAB brand automatic applicators – valued for their reliability, flexibility and integration with IT systems. You can easily adapt CAB devices to the requirements of production lines and logistics. They also perform well in harsh environments, making them an ideal choice for many industries.

No compromises - only proven solutions

Not sure which model will be best for your company? Contact our consultants – We will select the perfect solution for your process. Opt for automation with HKK Group and discover how much you can gain from modern label applicators.

CAB Hermes Q label applicator

A versatile system for printing and automatically applying labels in real time.

Key parameters:

- Print resolution: 200, 300 or 600 dpi

- Label width: up to 108 mm (depending on version)

- Printing speed: up to 300 mm/second

- Possibility of continuous operation (24/7)

- Interfaces: USB, Ethernet, RS232, optional WLAN

Available with 2″ and 6″ print heads (print width)

Left and right versions (for flexible integration into the production line)

Ability to mount large label rolls: Ø 205 mm and 300 mm

Application:

- Production lines, logistics, automotive, electronics

- When high precision and reliability are needed in harsh industrial environments

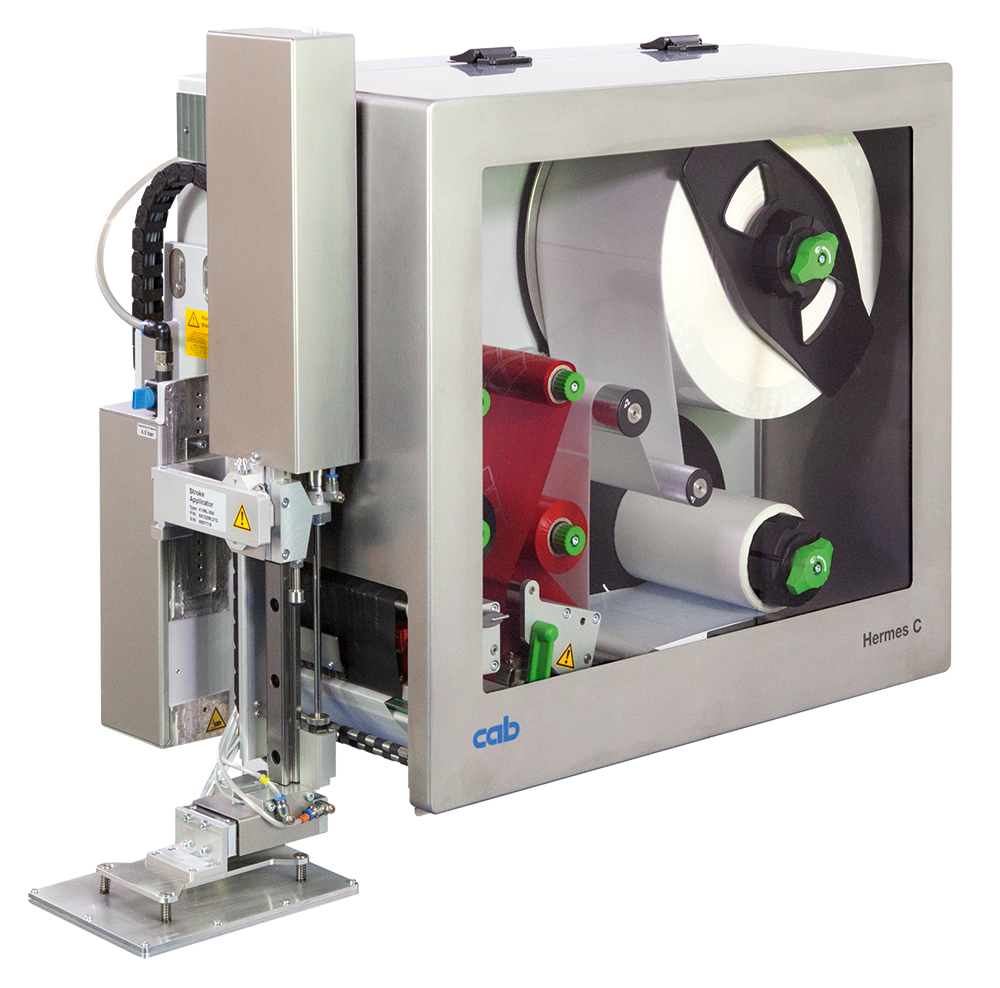

CAB Hermes C label applicator

Two-color industrial label applicator equipped with two printing modules to apply warning symbols and text in one pass.

Key parameters:

Two print heads (two-color printing)

Resolution: 300 dpi

Label width: up to 105 mm

Version with 6″ head only

Possibility of continuous operation

Precise integration with Hermes applicators

Application:

- Pharmaceutical, food, cosmetics industry

- Perfect for printing labels with graphic elements in different colors (e.g. GHS marks, logos, warnings)

CAB SQUIX 4 label applicator

CAB SQUIX 6

A modular series of industrial label printers with the ability to integrate with automatic application applicators – ideal for expanding automation systems.

Key parameters:

Print resolution: 200, 300 or 600 dpi

Label width: up to 108 mm (SQUIX 4), up to 168 mm (SQUIX 6), 2″ version also available

Printing speed: up to 300 mm/second

Ability to work in print & apply mode with a wide range of applicators

Handling product labeling in motion, at rest, and on flat and curved surfaces

Application:

- Industrial production, logistics, labeling of cartons, trays, products.

- A very flexible solution for companies planning step-by-step automation development.

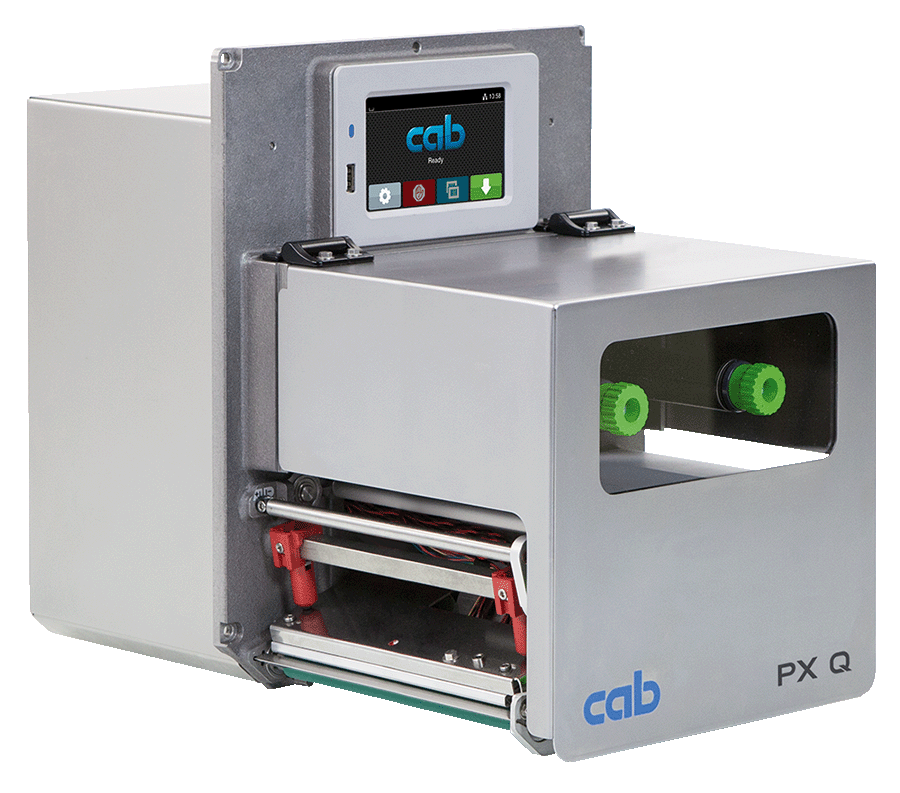

CAB PX Q label applicator (Print Module)

A compact printing module designed for integration into existing production lines or custom application systems.

Key parameters:

Print resolution: 200, 300 or 600 dpi

Label width: up to 168 mm

Printing speed: up to 300 mm/second

Dedicated for installation in automatic systems and OEM applicators

Application:

- Automated lines, industrial robots.

- OEM integrations – ideal where full integration with your own label application system is required.

Compare applicator models

| Model | Type | Print resolution | Label width | Print speed | Applicator type | Typical application |

|---|---|---|---|---|---|---|

| Hermes Q | Printer + applicator | 200 / 300 / 600 dpi | Up to 108 mm (2″, 4″, 6″ versions) | up to 300 mm/s | In motion, at rest, flat and curved surfaces | Industry, electronics, automotive |

| Hermes C | Dual head printer (two-color printing) | 300 dpi | Up to 105 mm (6″ version) | up to 250 mm/s | Integrated into the printing system | Pharmaceuticals, cosmetics, two-color printing (e.g., GHS) |

| SQUIX 2 / 4 / 6 + SQ1000/SQ3200/SQ3500 | Printer + interchangeable applicator | 200 / 300 / 600 dpi | Up to 108 mm (4) / 168 mm (6) | up to 300 mm/s | In motion, at rest, flat or curved product | Manufacturing, logistics, warehouses, stage automation |

| PX Q | Printing module for integration | 200 / 300 / 600 dpi | up to 168 mm | up to 300 mm/s | Dependent on build / OEM | Automated lines, OEM integrations, industrial robots |