Zebra Datalogic stationary industrial code scanners

We design and implement industrial automatic barcode reading systems – from single production stations, through process lines, to scanning tunnels, sorting plants and traceability systems. We offer solutions based on Zebra and Datalogic technologies, tailored to real production and logistics processes.

01/

Automatic scanning systems

What does the AutoID system project include?

- Selection of scanning and imaging technologies

- Design of posts, tunnels and reading points

- Integration with PLC, WMS, MES, WCS, SAP

- Application and PoC tests

- Industrial commissioning and 24/7 support

We create solutions that realistically work in production and logistics environments.

Where are automated industrial scanners used?

We rely on the reliable technology of our partners:

02/

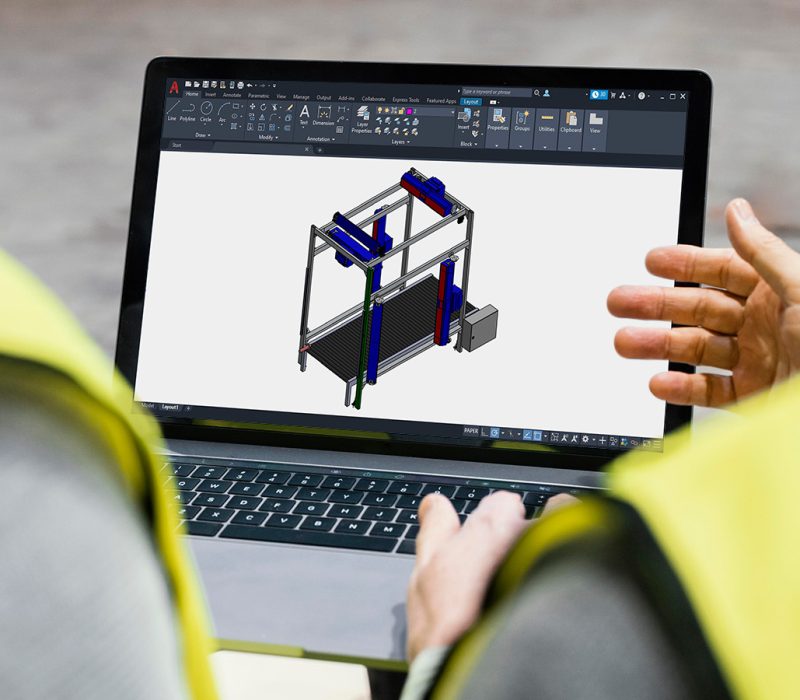

Engineering team with on-site experience

Automatic barcode scanners are today the foundation of modern manufacturing and logistics. They are used in traceability, quality control, sorting, packaging and advanced scanning tunnels and DWS systems.

Professional design of a stable scanning system, requires many years of experience and dozens of completed projects. With us you will increase efficiency, eliminate manual errors and achieve full process transparency.

How do we work?

03/

Solutions available in our offer

Compact industrial short-range scanners

The easiest way to automatically read codes at production and packaging stations.

Compact industrial scanners for point-of-use applications for automatic reading of 1D, 2D and DPM codes. Ideal for integration at production stations, packaging lines and simple traceability systems where reliability, fast deployment and 24/7 operation are important.

- Zebra FS10

- Zebra FS20

- Datalogic Matrix 120

- Datalogic Matrix 220

- Datalogic Blade

Advanced mid-range industrial scanners - OCR, DPM, traceability

For fast lines, difficult codes and advanced traceability.

Advanced industrial scanners for applications where standard solutions do not provide sufficient reading performance. Designed for traceability systems, DPM and OCR reading, high line speed operation and integration with industrial automation, WMS and MES systems.

- Zebra FS40

- Zebra FS42

- Zebra FS70

- Datalogic Matrix 320

High-resolution industrial scanners for tunnels, gates and large facilities

Automatic code reading in sorting plants, scanning tunnels and DWS (Dimensioning, Weighing, Scanning) systems.

High-resolution scanners for multilateral code reading on parcels, cartons and pallets moving at high speed. Used in scanning tunnels, courier sorting plants, distribution centers and Courier grade systems where maximum efficiency and 24/7 stability are key.

- Zebra FS80

- Datalogic AV500

- Datalogic AV900

- Datalogic AV7000 12K

BHS - Baggage Handling System for Airports

Automatic baggage identification and sorting systems in airport infrastructure.

BHS systems are specialized solutions for automatic reading, tracking and sorting of checked baggage at airports. They include scanning tunnels, logistics gates and RFID systems, providing very high read rates, continuous operation and full integration with airport and IT systems.

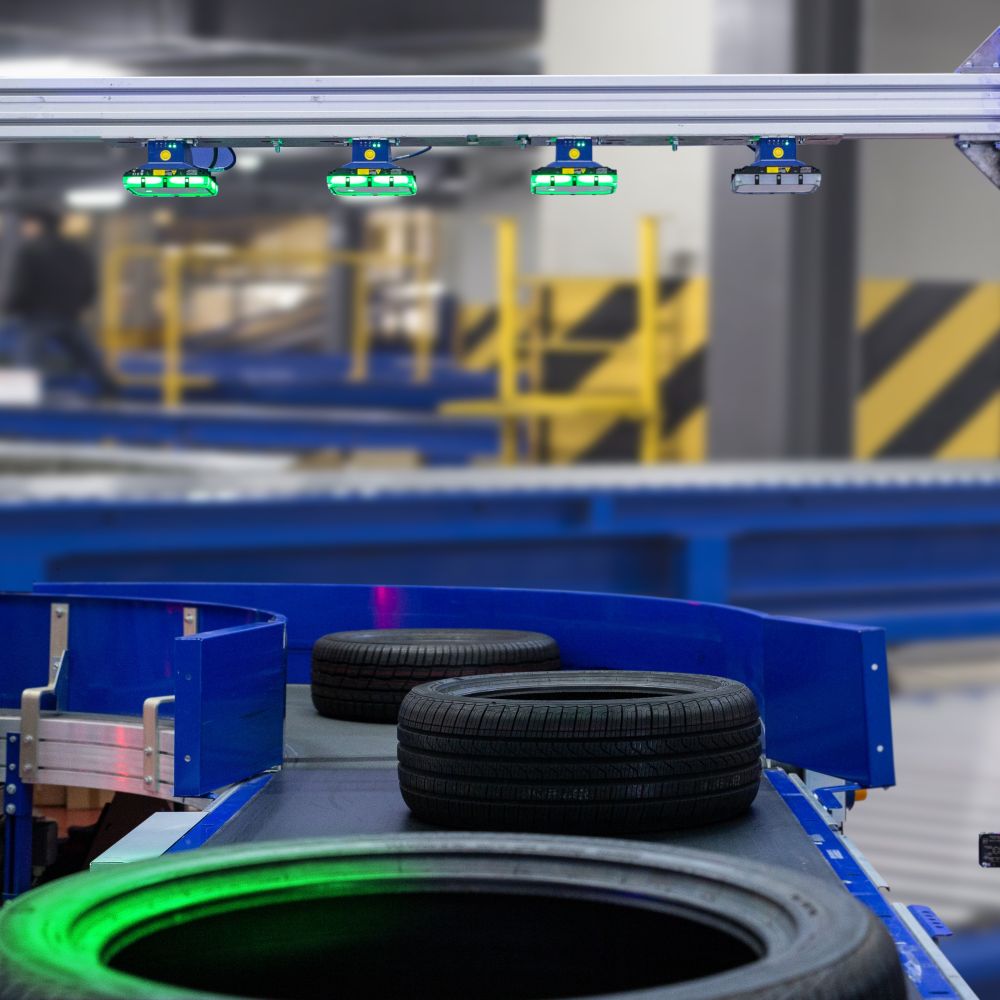

STS320 - industrial tire scanning and traceability system

A dedicated tire identification solution for tire manufacturing and distribution.

STS320 is a complete, factory-integrated scanning system designed specifically for the tire industry. It enables reliable tire identification, traceability and sorting throughout the tire lifecycle – from vulcanization to quality testing to logistics and warehousing.

Do you have a process that requires automated code reading?

Each production line and each warehouse operate differently.

We will select the technology, design the system and implement it in your environment.

04/

Contact with us

Sulisław Słomski

Account Manager - Automation Solutions

Wojciech Stachowiak

Head of Automation Solutions Department

Maciej Szulc

Account Manager - Automation Solutions