Shortcuts

- Automatic barcode scanners in industry and logistics

- What are automatic code scanners in industry

- What problems automatic scanning solves in industry

- Where automated industrial scanners are used

- Main classes of automatic scanners

- How the industrial automatic scanning system works

- Automatic scanning as the foundation of traceability

- Highlights

Automatic barcode scanners in industry and logistics

Automatic barcode scanners are a key component of modern manufacturing and logistics systems. They enable continuous, unattended reading of 1D, 2D and DPM codes without stopping the process, eliminating operator errors and providing consistent data for IT systems.

In practice, they are the foundation of traceability, quality control, WIP and automated intralogistics systems. A well-designed scanning system is not a “reader” – it is a source of process data on which automation, planning and quality are based.

What are automatic code scanners in industry?

Automatic barcode scanners are industrial identification systems that operate 24/7, without operator involvement, as an integral part of machines, production lines and logistics systems.

Unlike handheld scanners, an industrial scanning system consists of:

- scanners or CCTV cameras,

- optics and dedicated lighting,

- sensors and encoders,

- decoding and video software,

- Integration with PLC, WMS, MES and ERP.

In practice, these are industrial vision sensors whose task is not only to read the code, but also to provide reliable process information.

Modern systems commonly use platforms from manufacturers such as Zebra and Datalogic. Classes of solutions, including Zebra FS10/20/40/42/70/80 and Datalogic Matrix 120/220/320, AV500, AV900 and AV7000, form the basis for building systems – from single reading points to advanced scanning tunnels and traceability systems.

What problems does automated scanning solve in the industry?

Automated barcode scanners are being deployed not because “you need to read codes,” but because they solve specific operational problems:

- Manual scanning and data transcription errors,

- Lack of full traceability of the product,

- stopping the line for reading,

- uncontrolled WIP,

- difficulties in analyzing complaints,

- Lack of consistent data for MES and ERP,

- Bottlenecks in sorting and packaging.

In the systems we design, automated scanning ceases to be a point of control and becomes a continuous stream of product and process data.

Where are automated industrial scanners used?

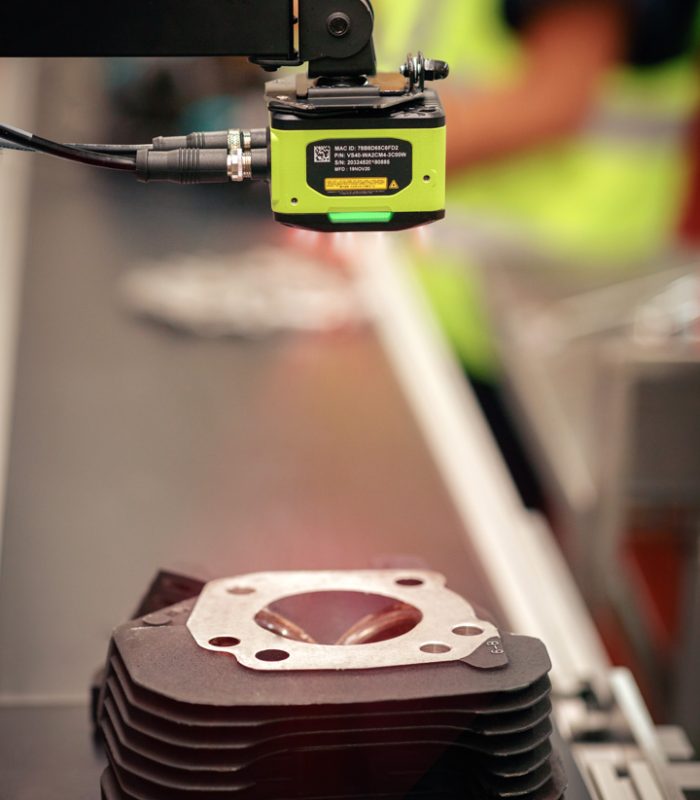

Manufacturing and assembly

Identify components, verify correct assembly, automatically load recipes and assign process parameters to serial number.

Packaging and labeling

Control the accuracy of labels, product-packaging compatibility and eliminate shipping errors.

Traceability and WIP

Building a product history from component to finished product and tracking work-in-progress.

Warehouses and distribution centers

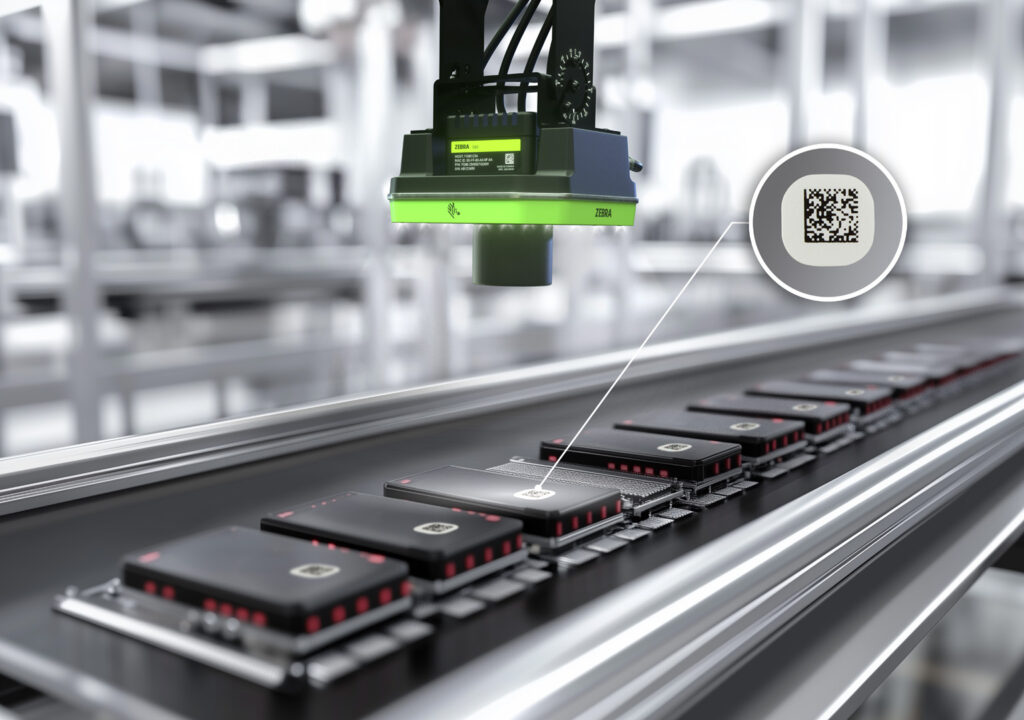

Automatic reading on conveyors, sorting plants and logistics gates.

Sorting plants and e-commerce

Identification at very high speeds and variable parcel orientation.

Scanning tunnels and DWS systems

Multilateral reading, OCR, image recording, and integration with Cubiscan weighing and dimensioning.

Specialized systems

Airports, tire industry, pharmaceuticals, electronics.

Main classes of automatic scanners

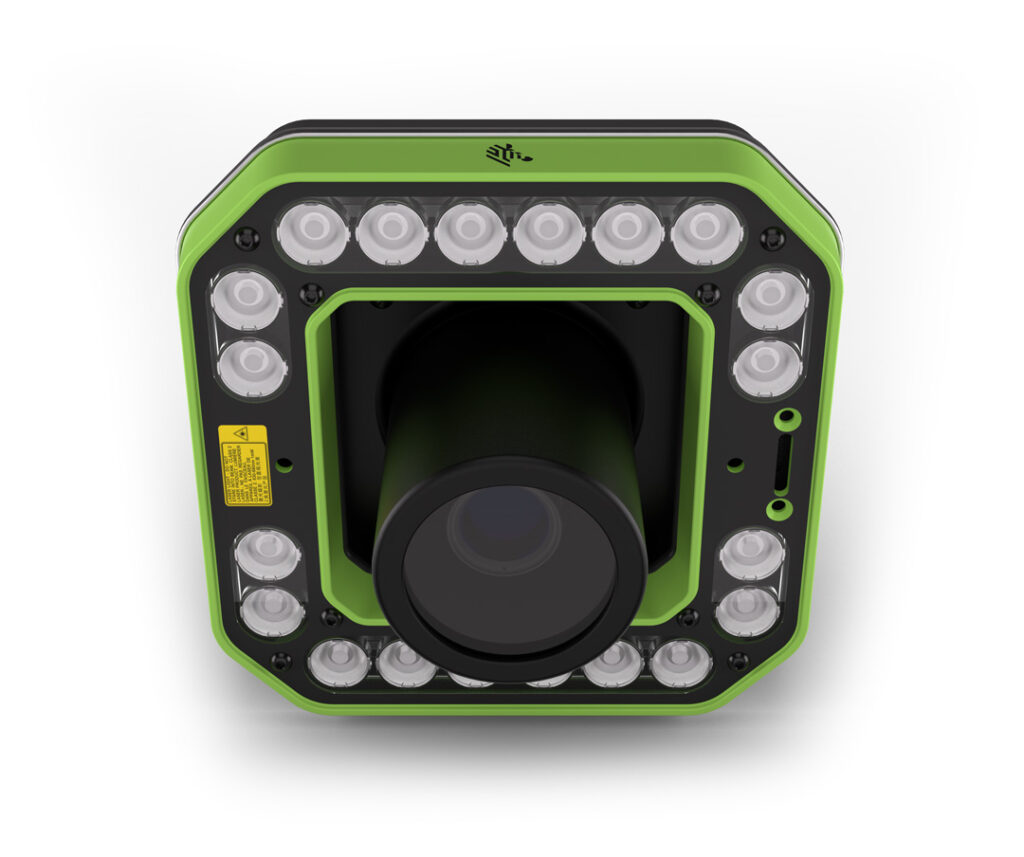

Compact short-range scanners

Used on workstations and machines to identify workpieces, components and labels. Typical grades: Zebra FS10 / FS20, Datalogic Matrix 120 / 220.

Advanced industrial scanners

Designed for DPM, OCR, high speed and simultaneous reading of multiple codes. Typical grades: Zebra FS40 / FS42 / FS70, Datalogic Matrix 320.

High resolution scanners for tunnels and gates

Build multi-camera architectures for sorting plants and tunnels.

Typical classes: Zebra FS80, Datalogic AV500, AV900, AV7000.

Dedicated systems

Complete solutions designed for specific industries (airports, automotive, tire industry).

How does an industrial automatic scanning system work?

Scanning system combines the hardware and software layers:

object identification,

synchronization with movement,

Decoding, OCR and image storage,

quality analysis,

Communication with PLC and IT systems.

In tunnel systems, the scanners work as a synchronized network, performing object tracking, image saving, video coding and full diagnostics.

Automatic scanning as the foundation of traceability

Traceability begins on the shop floor.

Automatic scanners:

-

link the product to the process, machine and parameters,

-

build WIP in real time,

-

enable complaint analysis and audits,

-

They feed the MES and ERP with reliable data.