Key information:

Progressive development of e-commerce

Recent years, have seen a significant acceleration in the development of alternative sales channels, especially online sales.

Today, without leaving home, we can purchase not only clothing, electronic equipment or toys, but also necessities, including fresh food.

The progressive development of e-commerce makes it particularly important to properly shape the internal logistics zone, which can become an area of competitive advantage generation.

The importance of innovation in logistics vs. economies of scale

Achieving a competitive advantage in the area of e-commerce logistics is possible with the commitment of adequate resources related to the creation of an IT infrastructure befitting the challenges of the world of online sales.

It is characterized primarily by the need to respond quickly to orders coming in almost around the clock.

The standard of service is becoming the dispatch of goods already on the day of the order or the next day.

The basis for achieving such efficiency is the perfect organization of logistics based on the use of modern technologies.

A key element of such an organization is the use of a WMS warehouse management system. It is an IT solution that covers all areas of work of a modern warehouse from the receipt of goods, through storage, to their shipment to the customer.

Even more productivity!

Very often, the warehouse system alone is not enough, so a modern and efficient warehouse is sometimes supported by additional tools that increase the capacity of internal logistics.

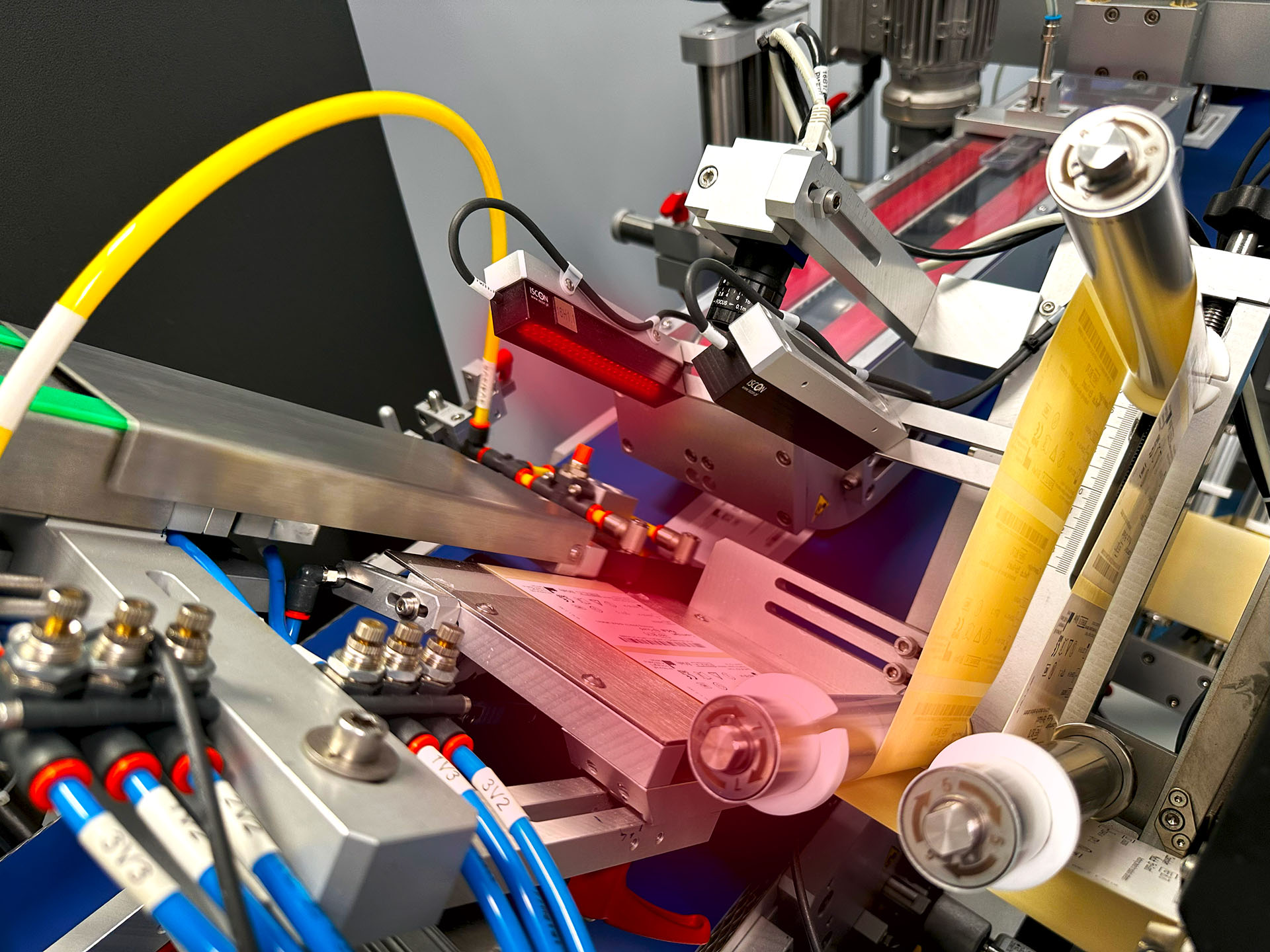

Such solutions include, first of all, voice picking systems, Cubiscan dimensioning systems, or warehouse automation elements.

The process of adapting a warehouse to the requirements of modern commerce is definitely cheaper when there are so-called economies of scale. We are talking about a situation in which this type of investment is not carried out for the first time and we are dealing with the existing structure of the organization, which can be easily replicated.

Such scenarios are far more common among logistics operators, but there is no shortage of companies that are successfully developing and upgrading their own warehouse.

Deciding which way to steer is not easy and depends primarily on the scale of operations and previous experience in warehouse logistics.

Which to choose? Your own warehouse or the help of a 3PL operator?

Deciding which way to steer is not easy and depends primarily on the scale of operations and previous experience in warehouse logistics.

In the case of start-ups, it will definitely be more advantageous to entrust all logistics to a specialized operator, who will take full care of ensuring that goods reach the right customer at the right time.

The entrepreneur will then be able to focus solely on running the business, developing the product portfolio or marketing activities.

For companies with their own warehouse, it often turns out that it will be most effective to bet on its process modernization to increase its capacity and capabilities. We’re talking about implementing a WMS and warehouse labeling system, rethinking alternative picking methods, or investing in equipment for sizing products and packages. Some entrepreneurs also use a combined model, engaging a 3PL operator for an operation at their own distribution facility.