Put To Light: A Revolution in Parcel Sorting

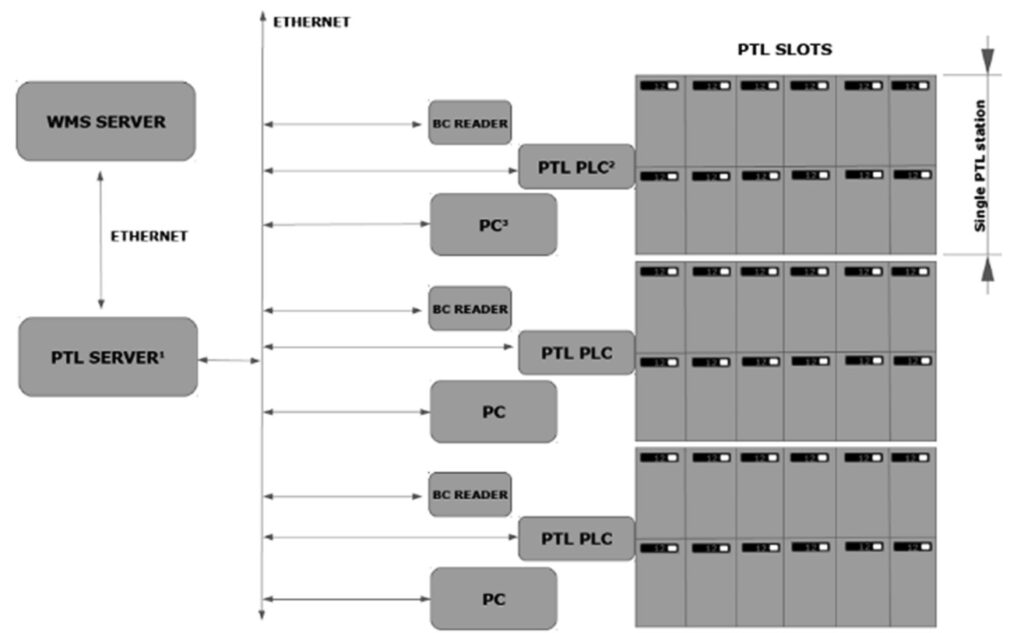

The company’s proprietary Put To Light (PTL) solution, supports the parcel shipping process by integrating sorting stations directly with the Blue Yonder Dispatcher WMS.

This state-of-the-art approach significantly increases productivity, improves process accuracy, speeds up shipping operations and reduces labor costs. With a short implementation time, the PTL system provides an effective tool for order management.

Why Choose Put To Light?

50% higher productivity

Greater accuracy

Accelerated shipping operations

Lower labor costs

Short implementation time

Key benefits of the PTL system

Optimal Use of the Team

Goods required for order fulfillment are delivered to PTL stations as a stream of multiple containers or pallets. This allows multiple operators to work simultaneously within a single picking wave, significantly increasing the efficiency of the picking team.

Reducing Parcel Preparation Time.

A semi-automated sorting process controlled by SKU, rather than by order, allows multiple orders to be processed simultaneously at a single PTL sorting station. This solution significantly speeds up the entire shipping process.

Key benefits of the PTL system

Simple Installation and Flexible Configuration

The components of the PTL system are ready for immediate use, with dedicated processes available in the Blue Yonder WMS for quick installation. The system can be flexibly configured using the standard functionality of Blue Yonder WMS, making it easy to customize the system to meet the specific needs of a warehouse.

Easy Expansion and Scalability

The warehouse can use multiple PTL stations to handle more orders in less time. Adding another PTL station is only a dozen hours of work. The system is scalable, and PTL zones can be easily adjusted or turned on/off depending on the changing impact of orders in the e-commerce process.

The Put To Light system significantly increases productivity, improves process accuracy, speeds up shipping operations and reduces labor costs. With a short implementation time, the PTL system provides an effective order management tool.

Components of the HKK PTL Solution

The integration of Put To Light with Blue Yonder Dispatcher WMS is based on an advanced library of functions. The pre-defined configuration of the PTL process in Blue Yonder WMS includes order selection, wave creation, picking, repacking, label printing and shipping. Central to the system is the HKK PTL application server, which manages the entire order sorting and picking process.

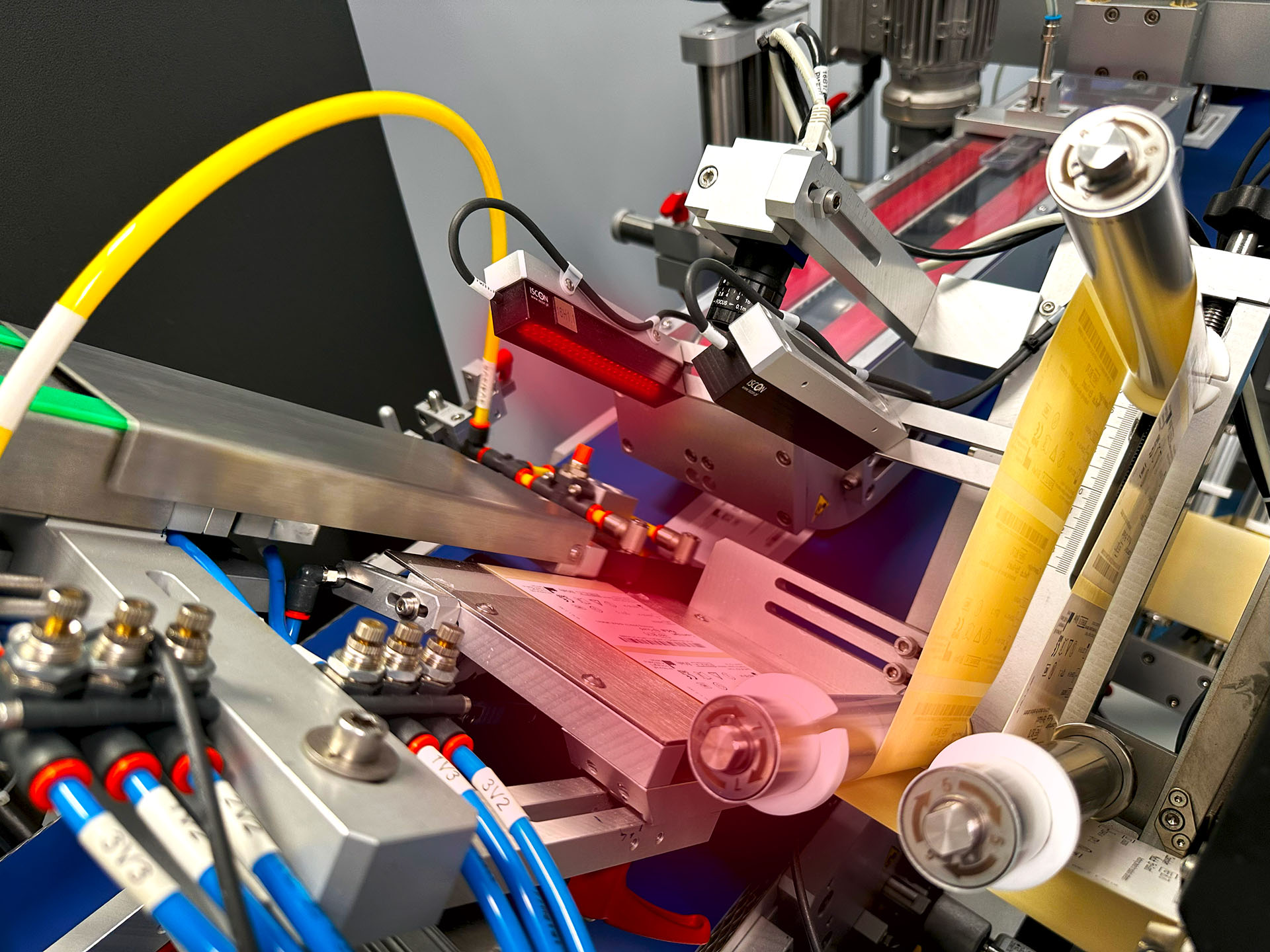

Each PTL station is equipped with:

- Touchscreen PC for administration and control

- LED panels with buttons

- PLC

- Barcode scanners

- Label printer

- Optional document printer and scale

How Does the Put To Light System Work?

- Order Filtering: Blue Yonder WMS filters orders that meet the criteria for the PTL process when they are loaded into the system.

- Order grouping: the system automatically groups selected orders into waves.

- Allocation and release of waves: waves are allocated and released for execution.

- Creating picking lists: Blue Yonder WMS creates picking lists for picks from the storage area to PTL stations.

- Delivery of goods: goods are delivered to PTL stations – various picking strategies are available, e.g. zone picking, bulk picking.

- Sorting into slots: the operator sorts goods into slots at the PTL station by scanning EAN codes and depositing products into slots marked by a blinking LED.

- Order completion: the rear LED panel indicates that the order is complete. The operator packs the goods from the slot and confirms completion by pressing the button.

- Closing packages: the package in Blue Yonder WMS is closed and the order status changes to Packed.

- Shipping: closed packages are moved to the shipping docks for loading and shipping.