Consequences of not verifying codes

Introducing a product with an illegible code into the supply chain has primarily financial consequences. There is an increase in the expense of handling the product, which is relatively easy to convert later into budget losses.

Other consequences are measurable image losses and even the possibility of breaking off cooperation with contractors who receive a defective batch of goods (e.g., retail chains).

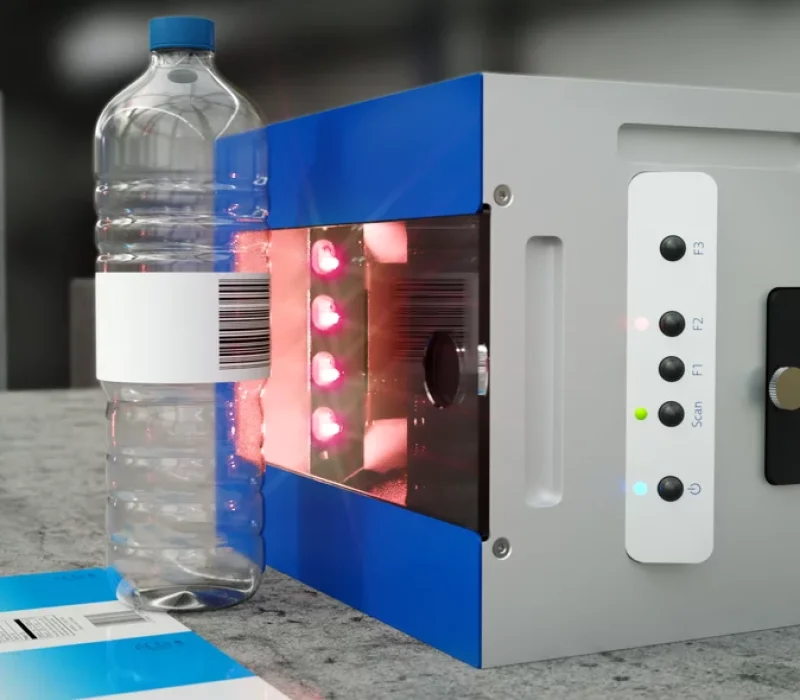

The use of measuring devices, such as barcode verifiers, makes it possible to effectively and almost 100% inspect barcodes and 2D codes, which will obviously prevent such situations.

Code verification in practice

The code verification process can be integrated into a dynamic sequence (in-line verification) or be a static process, independent of production or labeling (off-line).

In each case, the premise of verification is similar – to check and determine whether the barcode or 2D code placed on the label or, increasingly, directly on the product complies with requirements. These requirements are most often coding standards such as ISO standards, GS1 general specifications, AIM, FDA, UDI regulations and other industry guidelines, and sometimes the specific requirements of a particular customer.

A code verifier checks each code to ensure that it meets the given expectations, and at the end of such a process generates a corresponding score. It is important to be aware of the difference between verification and reading a code with a code reader (scanner). Only verification is a guarantee of its correctness, and thus the certainty that it will be read at any point in the supply chain (excluding the situation of its physical damage).

Benefits of code verification in a nutshell

Code verification - how to get started?

Choosing a method and equipment for code verification is not, despite appearances, a simple process. There is a large variety of code symbols on the market, both linear and, increasingly, 2D codes. This is compounded by the various requirements (norms, specifications, standards) we mentioned earlier.

We must also remember that each application is different. The way the codes are printed, the raw material they are placed on, are different, as are the expectations of the recipients. Implementing code quality testing is not only the cost of purchasing, operating and servicing equipment, but also often the need for changes in quality control and assurance systems, often included in ISO certificates.

That’s why it’s a good idea to entrust this task to a proven supplier with support from device and software manufacturers.

Our experience in code verification

For 30+ years we have been implementing solutions related to code quality improvement based on code verification. During this time, our specialists have implemented thousands of such devices, ranging from small printing houses, manufacturing plants, logistics units, to the country’s largest retail chains. Each implementation is preceded by a detailed analysis of the customer’s needs and conditions.

After purchasing the equipment, using our extensive experience, we provide assistance in analyzing and solving user problems. We have our own authorized service for equipment and accessories. Our advantage, in addition to our vast experience and continuous expansion of knowledge, is the wealth of solutions we offer.

Our partners and suppliers of code verifiers are recognized global manufacturers such as Axicon, REA, OMRON (formerly LVS and Microscan). The equipment offered includes both advanced in-line systems, including those integrated with label printers (ZEBRA, Honeywell or TSC Printronix), and more popular off-line solutions.

REA, Axicon barcode verifiers

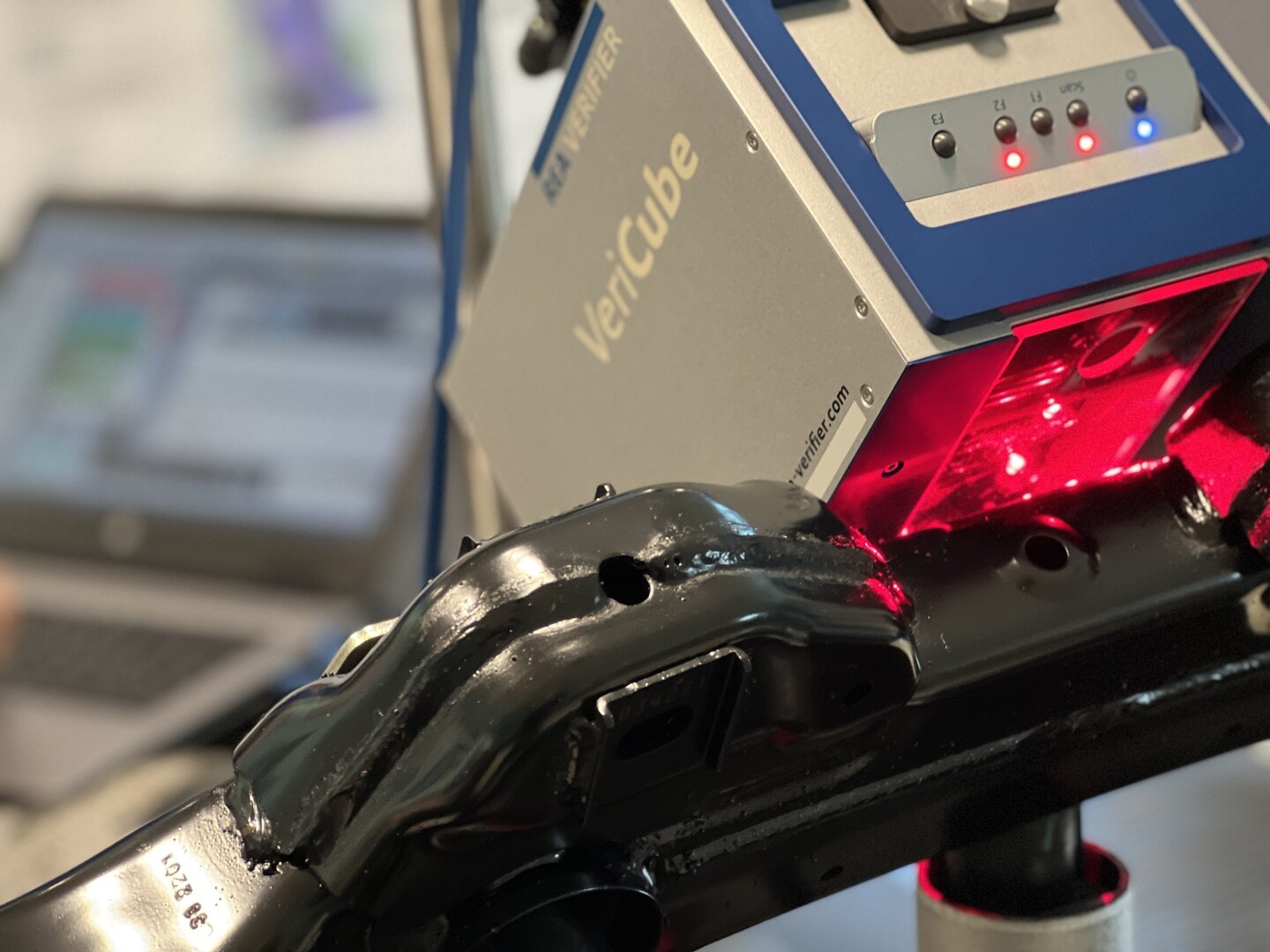

- REA VeriCube – the most versatile and option-rich verifier, especially appreciated in direct marking (DPM). Increasingly common in the automotive industry, but also in industries where specific software configuration expectations are required.

- AXICON 15200 and 15500 – verifiers liked for their lightweight design and simple software, especially common in pharmacy and GS1 solutions

- REA VeriMax – a verifier that combines offline and online features, sometimes referred to as a “near line” solution, increasingly appreciated in the industrial sector.

- REA VeriMax Mobile – new quality and possibilities in mobile verification, especially of 2D codes

Of course, all the time solutions dedicated to linear codes have their place in the market, which, due to their lower price and specificity, are still popular with customers

- REA PC-Scan – the highest measurement precision and self-calibration are unique features of this model.

- REA ScanCheck – laser precision, full mobility and the ability to measure both very small codes and codes on logistics packaging.

- Axicon 6100 and 7100 – the next iteration of linear models that have been proven for more than a dozen years, equipped with a unique feature of reading at multiple heights in a single survey.

Summary

Verification of barcodes and 2D codes is a key element to ensure their correctness and compliance with standards, which translates into a smooth functioning of the supply chain.

Improperly printed or damaged codes can lead to disruptions in logistics, additional costs and even loss of customers. Thanks to modern verifiers, it is possible to effectively control the quality of codes, both in-line and off-line, eliminating errors already at the production stage.

We invite you to contact us and talk to us, during which our consultants will help you choose an optimal and tailor-made solution.