Key information:

Measurement standards for barcode quality standards, were developed back in the early 1990s. These standards are updated periodically, and the most current versions (ISO/IEC) include indications not only for one-dimensional codes, but also for two-dimensional codes, such as Data Matrix, or QR Code.

Quality criteria analyzed

Measuring devices – barcode verifiers analyze the following quality criteria in the measurement process:

- Contrast between black and white fields.

- Reflectivity Index.

- Contrast of dash edges in the barcode.

- How stable the contrast between black and white remains throughout the code (modulation).

- Defects, that is, the presence of black dots in white spaces or white in dashes.

- Differences in the width of dashes and spaces (decodability).

- Checking the quality of code margins, check digit and data encoding (content decoding).

Based on the analysis of the indicators indicated above, the barcode verifier evaluates the barcode according to a numerical scale (from 4- best rating to 0 – unreadable code for the ISO/IEC standard). You can also use an alphabetical scale (A- best grade, F- unreadable code, for the ANSI scale).

Intermediate ratings imply a gradual decline in the quality of bar codes in the future, and it is up to specific users to determine the minimum acceptable rating of a code that can be approved for marketing. For 2D codes, the evaluation criteria are slightly different, but the rating scale itself remains similar.

Verifiers of linear codes (bar codes, 1D codes) must meet the standards defined in the ISO 15426-1 procedure, and verifiers of two-dimensional codes must comply with ISO 15426-2.

Working with barcode verifiers - what to pay attention to?

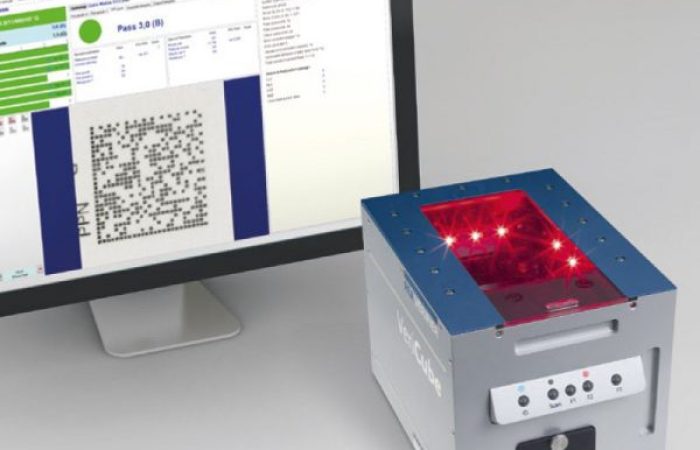

Barcode and 2D code verifiers, are precision measuring devices. Their design corresponds to the conditions in which they will be used-not only in laboratories, but also in warehouse halls or at the point of sale. However, the measurement peculiarities of verifiers dictate that they be handled in a special way, since barcode verification is based on generally recognized standards.

The result of the verification should be the same, regardless of the device used to carry it out (if it is, of course, a device that works in accordance with standards). To ensure standards-compliant operation, it is important to remember to calibrate equipment periodically . This process is done by reading calibration cards produced by ANSI (American National Standard Intsitute) certified suppliers.

During calibration, the operation of the device is adjusted, taking into account the degree of wear and tear, operating conditions (external lighting, temperature). Calibration should be performed regularly, especially when the verifier works connected to different computers (each switch between computers should involve calibration). Expiration date of calibration cards, is about 1 year.

In addition to regular calibration, care should also be taken to periodically inspect the verification equipment to identify components that may have worn out (for example, LED lamps that illuminate the code being verified). Any component whose operation deviates from the correct one can lead to misrepresentations in the verification process and, consequently, to incorrect code evaluation.

HKK Group - your expert in the area of code verification.

Our company has been helping customers optimize the application area of barcodes and 2D codes for more than 25 years. In our offer you can find a full range of verification products from recognized manufacturers such as Axicon, REA, OMRON. We also provide training services in the use and application of barcodes, service and calibration.