How are the attitudes of logistics and warehousing departments changing?

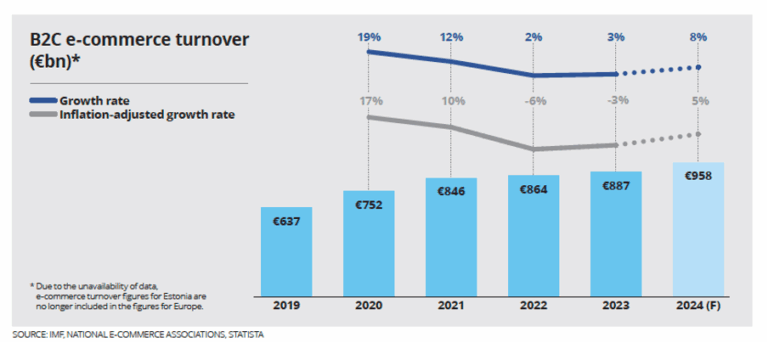

What is the main driver of change in warehouses? If we ask logisticians, they will definitely point to the growth of multichannel commerce. It is online sales that are changing the face of logistics – this sector is growing worldwide. Below are statistics on the growth of e-commerce in the European Union in recent years.

It is estimated that by the end of 2024 as many as 74% of Internet users will make online purchases. The frequency and volume of these purchases will increase in the years to come.

E-commerce - the specifics of multichannel commerce

Why must logistics change to meet the demands of e-commerce? Can’t orders from e-commerce stores be handled the same way as those from other channels? The answer depends on the specifics of multichannel commerce, in particular:

- The volume and frequency of customer orders,

- service quality requirements, especially shipping speed,

- The need to handle returns,

- specific packaging requirements and transportation choices,

- seasonality and the associated need for rapid scalability of operations.

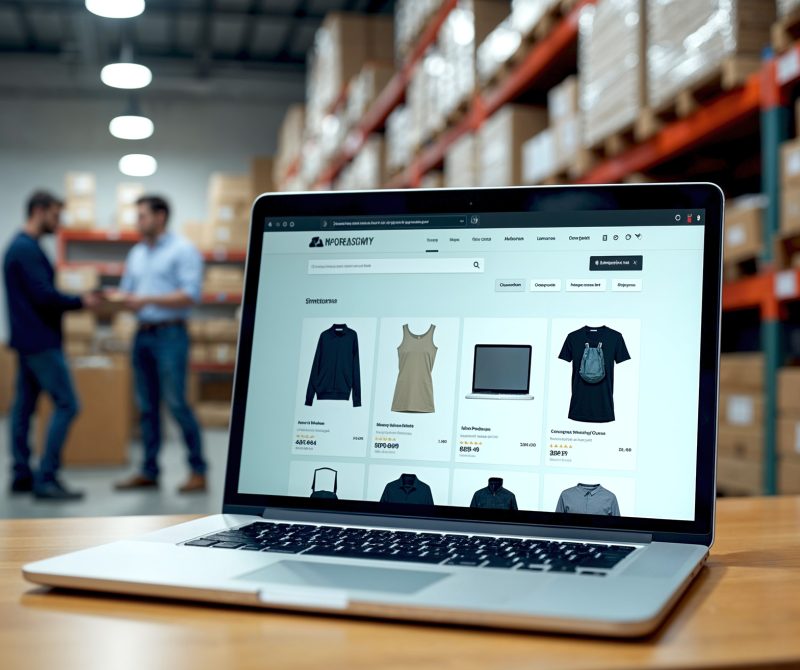

All these factors mean that handling e-commerce requires appropriate IT tools to optimize warehouse processes. Among the most popular are WMS class systems, but also ERP.

ERP system as support for logistics

An ERP (Enterprise Resource Planning) system is an integrated software for planning and managing an organization’s resources. As the name suggests, it covers all areas of a company’s operations – from finance to human resources, sales, purchasing and logistics.

Unlike systems that focus on a single slice of the business, ERP integrates all processes within a single IT platform, eliminating the need to combine different tools.

In logistics, ERP allows tasks to be recorded – from the moment a customer places an order to the shipment of goods from the warehouse. Integration with other modules allows logistics activities to be triggered by events in other areas (such as a placed order).

WMS system - computerized warehouse management

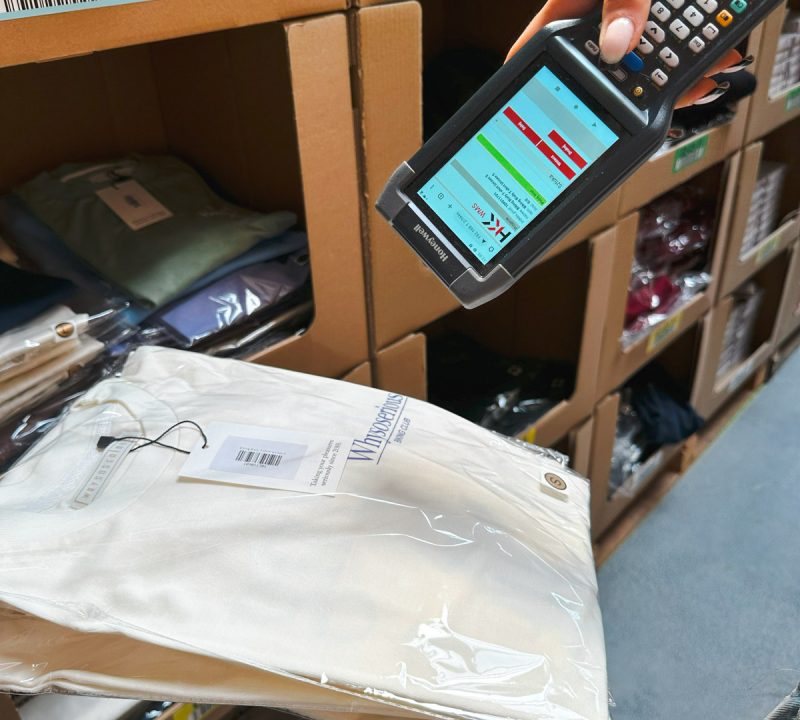

Unlike ERP planning systems, Warehouse Management System ( WMS) solutions are strictly management tools focused on organizing warehouse processes. A WMS is usually a separate solution, integrated with ERP through interfaces.

The WMS is responsible for the entire life cycle of goods in the warehouse: from receiving, to storage, to picking and shipping. It enables:

- Optimum use of storage space,

- Organizing the work of operators in a way that guarantees timeliness,

- minimizing mistakes,

- Selecting appropriate shipping packaging and reducing courier costs,

- Integration with warehouse automation systems,

- Rapid scaling during periods of increased demand,

- efficient handling of returns.

All this makes WMS an indispensable tool in e-commerce logistics.

WMS or ERP - summary

It is impossible to answer unequivocally which system – ERP or WMS – will be better without knowing the specifics of a particular enterprise. One thing is certain (and our experience confirms it): once a certain level of turnover and operational complexity is reached , both systems become indispensable.

ERP is responsible for the formal registration of enterprise-wide processes, while WMS is used to manage and optimize warehouse processes – continuously and comprehensively. The cooperation of the two systems gives the best business results.