Shortcuts

- AMR robots in the context of ROI – when does automation really pay off?

- ROI in practice: forklift operator vs AMR robot

- Comparison of monthly cost – 1st, 2nd and 3rd shifts

- Shiftability as a key factor in ROI

- Where do AMR robots pay for themselves the fastest?

- The most common concerns – and what the numbers say

- Summary

- Highlights

AMR robots in the context of ROI - when does automation really pay off?

The automation of internal logistics is increasingly ceasing to be an “innovation” project and becoming a rational business decision. Rising labor costs, a shortage of forklift operators, and pressure for process stability are causing manufacturing and logistics companies to look more and more closely at the return on investment (ROI) of AMR (Autonomous Mobile Robots). The key question today is not “whether to implement AMR,” but “if and when such an investment will pay off.”

The following analysis is based on the example of the solution AMR Robotize GoPal, widely used in multi-shift manufacturing plants and warehouses.

ROI in practice: forklift operator vs AMR robot

The starting point for any ROI analysis is the cost of labor. Let’s make conservative but realistic assumptions:

The average salary of a forklift operator: approx. PLN 6,000 gross,

The total cost to the employer (including PPK): approx. PLN 7,300 per month,

Which amounts to about PLN 87,600 per year per shift.

In practice, indirect costs such as sickness absenteeism, vacation, overtime, employee turnover, training and operational downtime must be added to this amount. In many plants, therefore, the real cost of maintaining an operator’s position is higher than the salary alone.

For the sake of comparison, let’s assume a complete AMR system (e.g., Robotize GoPal), including a robot, fleet management software, putaway stations and deployment. The total value of such a system may be about EUR 100,000, or about PLN 430,000. , and was taken as the basis for further calculations:

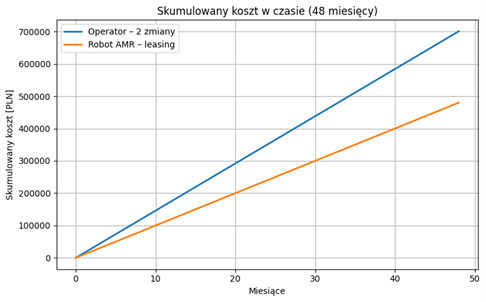

lease term: 48 months,

No initial deposit and redemption (to simplify the calculation),

monthly installment: approx. 10,000 PLN

(The assumed installment corresponds to an effective financing cost of about 5-6% per year).

With leasing, an AMR robot ceases to be a one-time capital investment and becomes a predictable operating cost that can be directly compared to the cost of labor.

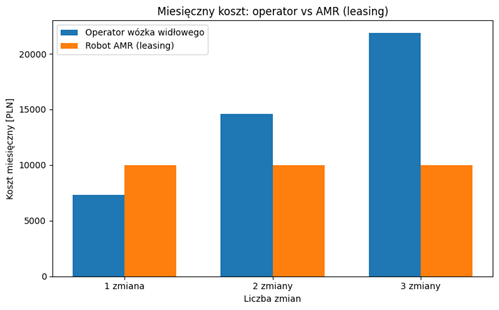

Comparison of monthly cost - 1st, 2nd and 3rd shifts

Even at this level , the break-even point is clearly visible . With one shift, the robot may appear more expensive, but with two and three shifts, the cost of labor increases linearly, while the cost of the robot remains constant.

Number of changes | Forklift operator – monthly cost | AMR robot – leasing (monthly cost) |

1 change | approx. 7,300 PLN | approx. 10,000 PLN |

2 shifts | approx. PLN 14,600 | approx. 10,000 PLN |

3 shifts | approx. 21,900 PLN | approx. 10,000 PLN |

Shiftability as a key factor in ROI

The biggest advantage of AMR robots is their availability. The robot can work 24 hours a day, and one charge (about 40 minutes) is enough for 9-11 hours of operation. Importantly, the robot:

does not take vacations,

no sick leave,

Does not generate absenteeism or turnover,

maintains consistent performance regardless of the time of day.

In a two- and three-shift environment, this means that a single investment supports multiple shifts, while the leasing cost remains constant. Even under the very conservative assumption that a robot replaces an operator on only one shift, in practice its utilization is much higher. This is why ROI is growing fastest in multi-shift plants.

Where do AMR robots pay for themselves the fastest?

Not every logistics process generates the same economic impact. The highest ROI is achieved where they occur:

Repetitive shipments of pallets or containers,

Long distances within the hall or warehouse,

Operation of production lines (known as milk run),

high-volume flow environments.

In such applications, AMR robots take over the most time-consuming and monotonous tasks, stabilizing processes and reducing dependence on personnel availability. Importantly, transportation automation does not mean eliminating people, but better utilizing their competencies in higher value-added areas.

The most common concerns - and what the numbers say

In conversations with companies, three arguments are most common:

“Robots are expensive.” – In the leasing model, the cost of an AMR robot is comparable to that of a full-time employee, and with multi-shift work it is often significantly lower.

“ROI is uncertain ” – with a clearly defined transportation process, ROI can be counted even before implementation.

“Deployment is complicated ” – with GoPal’s Robotize solutions, deployment does not require infrastructure rebuilding. The robots use SLAM mapping and move within the existing environment, and integration can be performed by both operators and WMS systems or MES.

In practice, it is increasingly the lack of automation that represents a greater business risk than its implementation.

Summary

AMR robots are no longer a futuristic curiosity, but a concrete tool for optimizing operating costs. A key change in the approach to ROI is leasing, which allows AMR to be treated as an operating expense comparable to FTE, rather than a one-time capital investment.

In companies working two or three shifts, the cost difference between human and robot labor quickly becomes apparent. In this view, the automation of internal transportation ceases to be a question of “if” and begins to be a question of “when” – and how quickly an organization wants to become independent of rising labor costs.