WMS as the foundation of modern warehouse logistics

WMS systems have been gaining popularity for many years, not as a trend, but as a necessity due to increasing pressure for speed, accuracy and transparency in warehouse processes.

The rapid growth of e-commerce and customers’ expectation of instant order status information make traditional warehouse management no longer scalable.

A modern WMS enables:

Full control over the movement of goods,

Eliminating picking errors with pick by voice or mobile terminals,

Automation of label printing or automatic application,

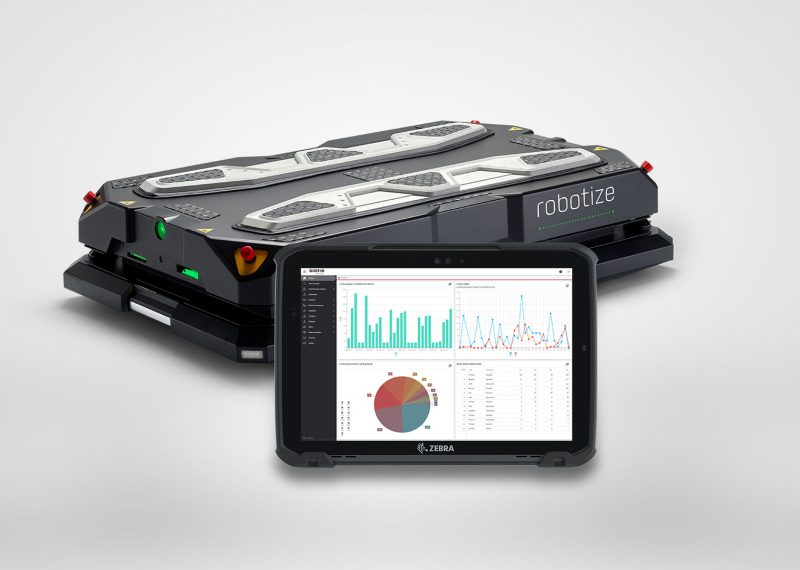

Integration with warehouse automation, RFID, and auto ID devices,

Handling e-commerce processes with high precision.

It’s a strategic part of the supply chain today, without which scaling the business becomes risky.

Growing customer expectations and market demands

The year 2024/2025 has brought further changes in consumer behavior: shorter SLAs, higher order volumes and greater demand volatility. Companies that do not have adequate IT infrastructure in the warehouse face:

downtime due to human error,

The inability to respond quickly to spikes in demand,

rising labor costs,

Lack of transparency and data for decision-making.

WMS eliminates these barriers by providing real-time data, allowing better resource planning, creating a digital twin warehouse, and automating repetitive activities.

Why is the turn of the year the best time to decide on a WMS?

1. optimal budget planning

Companies are reviewing their operational performance and needed investments right now. The purchase and implementation of warehouse system – from process analysis(logistics consulting) to the launch of the solution, is a project worth planning in advance.

2. realistic possibility of implementation at the start of the new season

Implementations of WMS, especially complex systems of the class Blue Yonder WMS, take from several months to a year, depending on the complexity of the processes and warehouse automation. The decision in the winter means operational readiness before the sales peak.

3. increasing pressure for digitization

More and more companies are declaring that digitization of the warehouse has become a strategic priority, not an add-on. Without automatic identification (RFID, scanners, self-adhesive labels), without product sizing, without systemic picking management, it is difficult to remain competitive.

4. a WMS is a future-proof investment

The market is changing rapidly – automation, robotics, vision systems, or digital twin solutions are developing at a record pace. A good WMS must be a foundation that:

Integrates with warehouse automation,

supports new auto ID technologies,

scales with the business.

How do you choose a future-proof WMS?

A forward-looking system is one that:

has an open architecture and API,

Works with auto ID devices and logistics automation,

Has a stable development roadmap (e.g., Blue Yonder WMS),

- provides advanced reporting and analytics,

supports solutions for retail, omnichannel and e-commerce.

It’s an investment that affects the entire organization – from IT to production to warehouse operations. If the warehouse is operating at capacity, the number of errors is increasing, the volume of orders handled is becoming difficult to manage, and processes need to be digitized – yes, this is a good time.