Industrial scanners for reading barcodes

Barcode and two-dimensional (2D) code technologies have become a permanent fixture in industry. Whether controlling the circulation of raw materials, the production process or the operation of a warehouse – a code scanner significantly speeds up work and increases its security.

In this article, we outline which devices to choose in order to fully exploit the potential of automatic identification technology, even in harsh environments such as the chemical and metallurgical industries.

Heavy duty handheld scanners

Selecting a barcode scanner or a 2D code scanner for industrial applications, it is worth paying attention to a robust, durable housing. The standard in this category of devices is IP65/IP67 waterproofing. This means full protection against dust and resistance to liquids, and in the case of the higher class (IP67) – also the possibility of short-term immersion in water.

Another key feature is the scanning module, which allows fast and precise reading of both 1D and 2D codes – even from several meters away. Depending on your needs, industrial scanners can connect to the central system either wired or wirelessly (Bluetooth, Wi-Fi). This makes them a flexible tool in warehouse logistics and production.

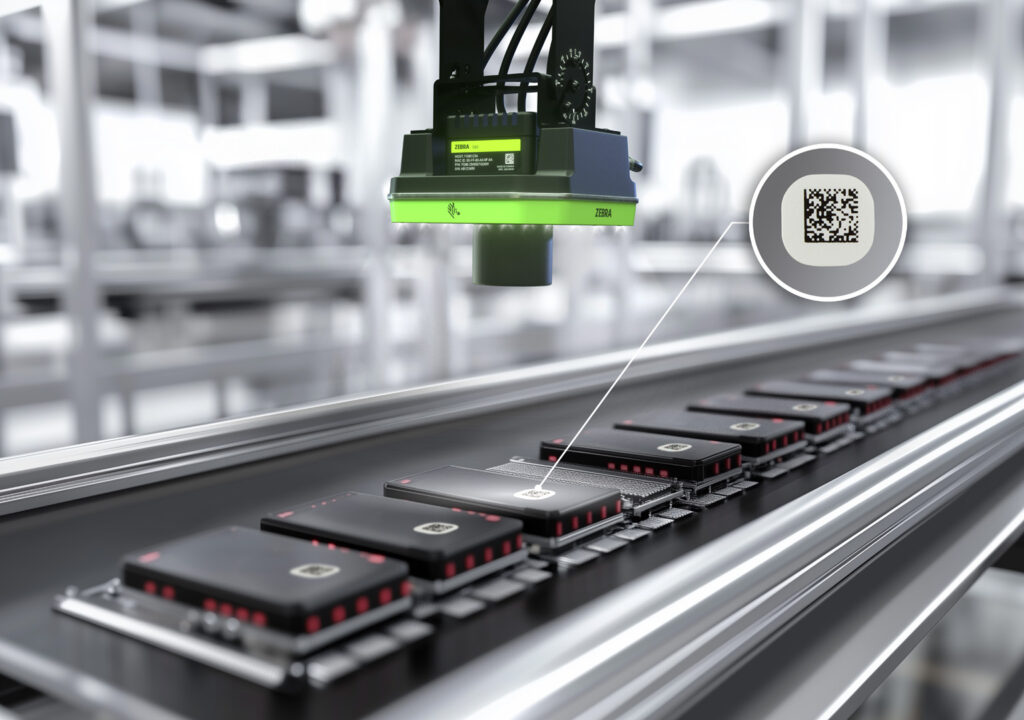

Fixed devices - industrial fixed scanners

Stationary industrial scanners are designed for processes that do not require constant operator support. They are ideal for a wide range of industries – from logistics to manufacturing. They can operate in linear, single-plane, omni-directional or image analysis mode.

The most common applications are:

shipping and receiving of goods,

Dimensioning and weighing using Cubiscan systems,

Traceability and traceability of work in progress (WIP),

reading DPM (Direct Part Marking).

Stationary scanners support warehouse and production automation and manufacturing, increasing process accuracy and facilitating integration with WMS systems.

Machine Vision - the future of automatic identification

Increasingly, industry is using systems Machine Vision. With digital cameras, sensors and 3D technology, it is possible:

Instant reading of large amounts of information (e.g., multiple codes simultaneously),

Quality control and verification of correctness of labeling,

Supporting robotic systems (e.g., precise robot positioning).

By combining Machine Vision with analytical algorithms, the system not only detects anomalies, but can also predict and prevent them. This solution is part of the trend digital twin and advanced logistics automation.