How to automate internal logistics quickly and relatively easily?

Manual work in a warehouse is an ideal candidate for automation. Most internal logistics activities meet three key considerations when considering: to automate or not to automate?

Repeatability – how many times a day can a pallet be transported from point A to point B?

Low ergonomics – which warehouse operator hasn’t complained of back pain after an entire shift of laboriously flipping cartons?

Low job attractiveness – The industry has struggled for years to recruit workers for manual handling positions.

The current level of technology development allows robotization and automation of many warehouse processes. This does not mean the complete replacement of man by machine, but rather the collaboration of man and robot. Importantly, the implementation of such solutions today is simpler and cheaper than you might think.

How is warehouse robotics changing and why is automation so easy today?

The process of robotization and automation of warehouse logistics has undergone huge changes in recent years. The first automation systems were based on vehicles moving along strictly defined routes – physical tracks or codes read as they moved.

Today, thanks to the development of vision, sensor and sensing technologies, autonomous robots (AMR) no longer need a specially prepared environment. They can operate in a typical warehouse, cooperating with operators without separating human and machine movement.

Types of robots used in the warehouse

Modern warehouse automation is not only AMR robots. Among the most popular solutions we distinguish:

ASRS systems – automated shelving and picking robots from dedicated locations.

Collaborative robots (COBOTY) – support workers in the process of picking and transporting products.

Palletizing robots – build pallets according to data from a master system, such as a WMS.

Labeling robots (print & apply) – automate the wrapping of products and pallets with with self-adhesive labels, supporting the process of automatic identification.

Packaging robots – adjust cartons to the size of the product in the shipping process.

Goods-to-Man systems – fully automated warehouses, designed mainly for large, specialized logistics centers.

Robotize robots in the warehouse

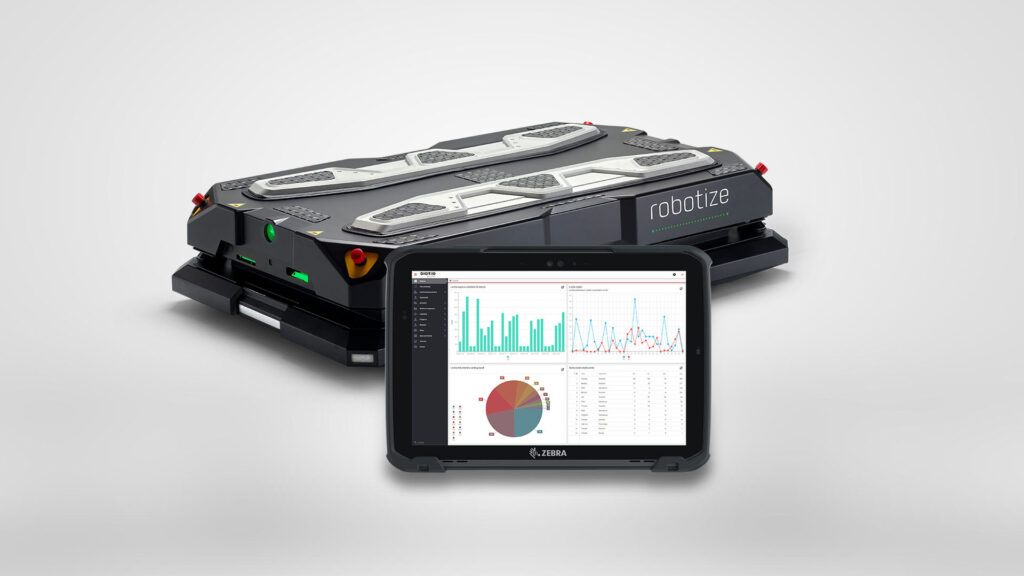

One of our key partners in robotization is Danish manufacturer AMR – Robotize. Its product range includes pallet transport solutions: GoPal 22 and GoPal 24, which enable the transportation of loads weighing up to 1,200 kg.

The hallmarks of GoPal ‘s robots are high precision performance – they perform well even in warehouses with limited space – and instant implementation into existing infrastructure.

In contrast, the model GoPal 35 supports the collaboration of operators and AMR trucks – it can carry picking baskets and assist in the picking process.

Integration of robots with host systems

A key element of any robot deployment in a warehouse is the integration with overarching systems, primarily the WMS system (Warehouse Management System).

In some cases, integrations with MES systems (Manufacturing Execution System) or ERP.

HKK Group’ s team of technical consultants implements integrations based on a variety of methods – from classic interfaces to APIs, which is currently one of the most popular, fastest and least fail-safe ways to connect systems.

Warehouse automation is no longer a futuristic plan - today it is a real investment with a quick return. Robots do not replace people, but relieve them of the heaviest, repetitive tasks, improve ergonomics and productivity. The collaboration of man and machine is the direction that defines modern warehouse logistics.