A WMS (warehouse management system) is an IT tool, the proper use of which can bring many benefits, generating a significant competitive advantage in the area of warehouse logistics.

This advantage is marked primarily by a significant increase in operational efficiency, a reduction in the incidence of errors during the preparation of goods for shipment proper to zero, and improved transparency and quality of service.

However, in order to take full advantage of the potential of a WMS, it is important to choose a WMS provider thoughtfully. What does this mean in practice and how can it translate into your benefits?

First of all, experience in the area of logistics process optimization.

A good and well-thought-out WMS is the result of many years of work and development resulting from the experience of working with customers from different industries, with different requirements and expectations. It is not possible to create a modern, functional and stable system in just a few months.

When considering the choice of a vendor, it is worthwhile to review the vendor’s history, ask how long the system has been developed, whether the vendor has an update policy, and whether the system is continuously developed.

Only an experienced and proven supplier will ensure proper implementation of the WMS, as well as its long-term operation in the structure of a warehouse or distribution center.

Good WMS implementation only with the right people.

The successful implementation of a WMS depends largely on the quality of the project team, which is why we suggest that you pay attention to the composition of the team when starting cooperation. There is nothing inappropriate in directing a question about the professional experience of the consultants involved in the implementation.

The WMS itself, its capabilities and functions are of course very important, but no less important is the experience, knowledge and design intuition of consultants and developers. Acquiring a WMS means taking advantage of the best practices involved in running the entire project and adopting an open-minded attitude towards the concept of optimizing your logistics, which will be created based on the experience and practice of those involved in the process.

The WMS itself, its capabilities and functions are of course very important, but no less important is the experience, knowledge and design intuition of consultants and developers.

Implementation methodology - use proven methods.

It is very important that the implementation process is conducted in accordance with a

consistent methodological concept

, which a good supplier develops over years of experience.

Task scheduling, an attitude of dialogue with the customer or the use of developed training patterns. Among other things, these elements can significantly speed up the implementation of a warehouse management system, and thus reduce the cost of the entire investment.

In our view, a methodology that draws on PRINCE 2 principles works best. It is very important that the project coordinator on the WMS provider’s side knows how to use it to its full potential, and has the power to ensure that its rules are followed by all participants in the project group (including those on the client’s side). Remember that implementing a WMS is a challenge that involves both parties.

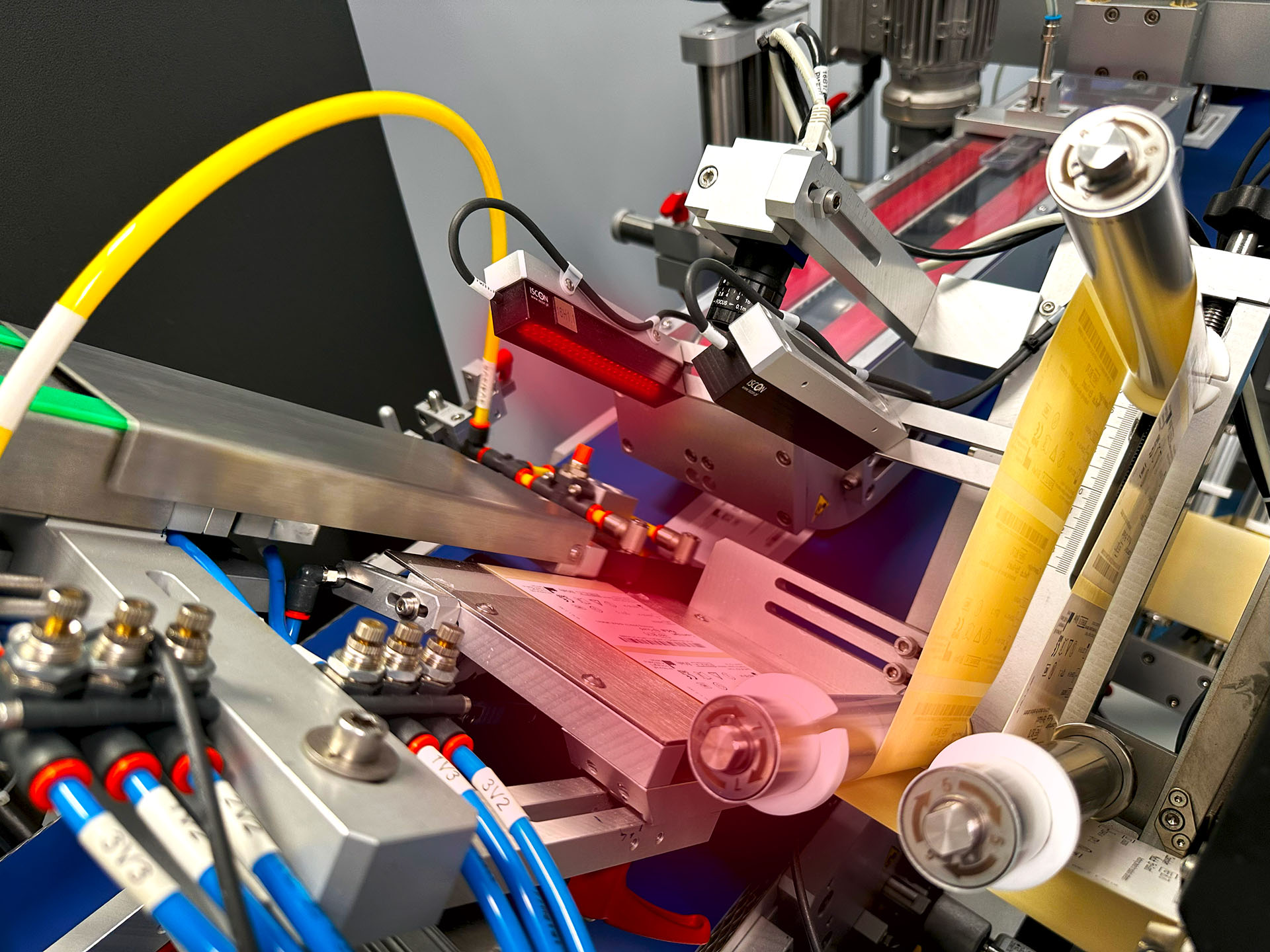

Industry knowledge - WMS without technology support means nothing.

Look for vendors that offer more than just implementing an IT solution. A WMS works on the basis of a number of technologies, the most important of which is definitely barcode technology, but also WIFI wireless network technology, or technologies related to process automation, elements of video data collection, or product dimensioning. Also essential to the operation of the system is

auto ID equipment

, such as data collectors, label printers or barcode scanners, and proper warehouse labeling.

Choose such a WMS provider who, in parallel, will also become your technology partner open to new opportunities, educating you about changes and breakthroughs related to the world of warehouse logistics and incorporating them into the development policy of your WMS.

It’s good to work with a learning organization that cares about its potential, offering cutting-edge solutions on the market.