Automatic identification technology

Automatic identification (Auto ID) technology is the foundation of modern warehouse logistics, e-commerce, manufacturing and service sectors. It makes it possible to quickly and accurately read data from labels, 1D barcodes and 2D codes. The choice of the right code scanner (such as a mobile terminal, data collector or stationary scanner) directly affects the efficiency of processes, reduction of errors and comfort of operators.

In this article, we explain the differences between 1D and 2D codes, suggest when to use each technology, and discuss which equipment will work best for different applications.

1D barcode - the classic of automatic identification

One-dimensional (1D) barcodes are commonly used in retail, warehouses, contract logistics, distribution centers and manufacturing. They are characterized by a simple structure – the information is written in the form of black lines of varying thickness.

Advantages of 1D codes:

Low cost of implementation and operation,

high reading speed,

Compatibility with older laser scanners,

Limitations:

less data capacity,

larger label area,

The inability to encode sensitive data in a secure manner.

Examples of applications: warehouse labeling, self-adhesive labels on products in retail, quick identification of goods in picking and inventory processes.

2D codes - greater capabilities and security

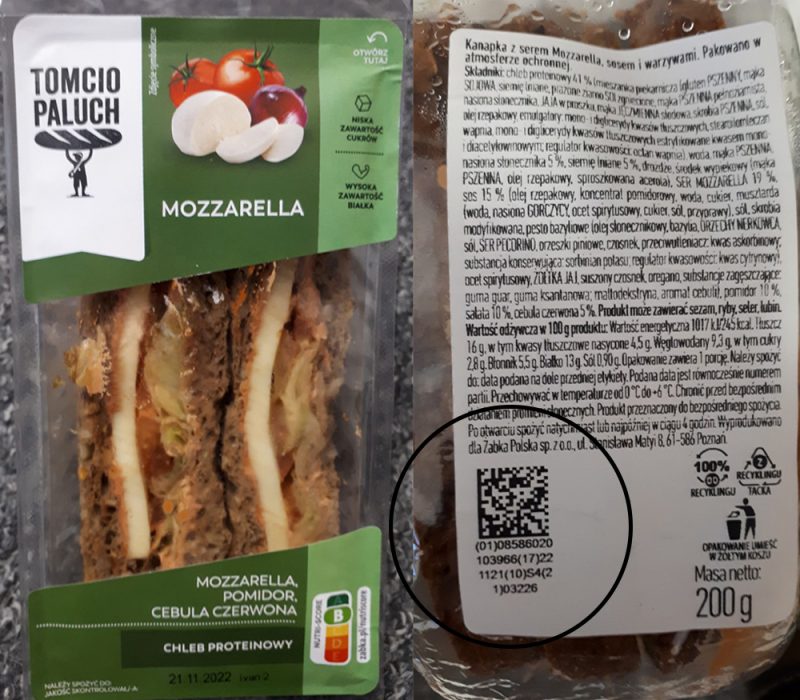

Two-dimensional (2D) codes – including the popular QR, Data Matrix or PDF417 codes – can store much more information than 1D codes. Their design allows them to be read even if up to 30% of the code area is damaged.

Advantages of 2D codes:

incomparably larger data capacity in a small space,

high resistance to damage,

The ability to encode sensitive data,

Versatility – reading by imager scanners, mobile terminals and smartphones,

application in future technologies, e.g. digital twin, supply chain tracking(traceability).

Examples of industry applications:

Pharmacy – protection against drug adulteration,

Food industry – access to detailed product information,

e-commerce – Customer interaction through QR codes on packaging,

warehouse automation – Integration with label applicators and industrial printers.

1D vs 2D code readers - key differences

1D (laser) scanners:

Fast reading of barcodes from a long distance,

low purchase cost,

Ideal for simple processes in logistics and retail.

2D (imager) scanners:

Reading both 2D and 1D codes,

The ability to scan multiple codes simultaneously,

OCR (text recognition) support,

Integration with data collectors, panel computers and mobile devices.

Automatic identification - an investment in the future

Auto ID solutions, such as 2D codes, RFID and pick by voice, are becoming a cornerstone of Industry 4.0. Their application in warehouse logistics, e-commerce and manufacturing allows to increase efficiency, minimize errors and improve process safety.

By choosing 2D technology and compatible scanners, you are preparing your business for the demands of tomorrow’s market – including integration with product dimensioning, warehouse automation and digital twin systems.