Key information:

Such a multichannel model (multi-channel commerce) brings with it a number of challenges, including for logistics. They are primarily related to the lower predictability of events, their greater variety, and thus the need to maintain a very flexible organization of logistics and warehousing departments.

In this article, we’ll talk about how HKK WMS and Blue Yonder WMS, can support the order picking process, so that your warehouse becomes an element of lead generation, not a cause of… trouble.

Modern picking strategies supported by our WMS.

The WMS can support picking of goods in the warehouse using various models and matching auto ID devices. Historically, at a time when distribution was mainly through the traditional channel, picking using forklifts was the most popular. With their help, pallets (whole or mixed) were brought to consolidation sites, from where they were loaded into delivery trucks.

One of the picking strategies is the solution of creating a special matrix in the consolidation field. Each matrix represents a different consignee, and the goods are deposited in the corresponding field which facilitates later shipment.

Another type of picking is the use of equipment, such as carts with compartments used to select the goods to be picked and deposit them in the appropriate place, representing the customer.

The picking process can also be looked at from the perspective of process strategy. Traditionally, we have dealt with discrete picking, with one operator per order. However, the rapid development of omni-channel commerce has made the so-called “multichannel” gain in popularity. A multi-order picking strategy, in which it is the operator who, overcoming the picking path, picks products for multiple orders.

Our WMS also supports a number of other picking methods, such as zone and wave picking. In the case of the former, the warehouse is divided into zones, and an operator or operators are assigned to each zone. They only complete the goods present in a given zone, but for multiple orders at the same time. The second type is wave picking, in which the warehouse is divided into zones and picking is done in given time periods.

Technology in the service of warehouse picking. The power of WMS integration.

The picking process supported by the WMS runs smoothly thanks to, among other things, the use of modern information and communication technologies.

The primary technology used in warehouse logistics, is barcode technology, which provides the ability to quickly and accurately identify the products to be completed and the zones from which picking should be carried out.

Our warehouse management system can also be supported by voice picking technology, which provides the ability to conduct picking by communicating with the WMS through voice commands.

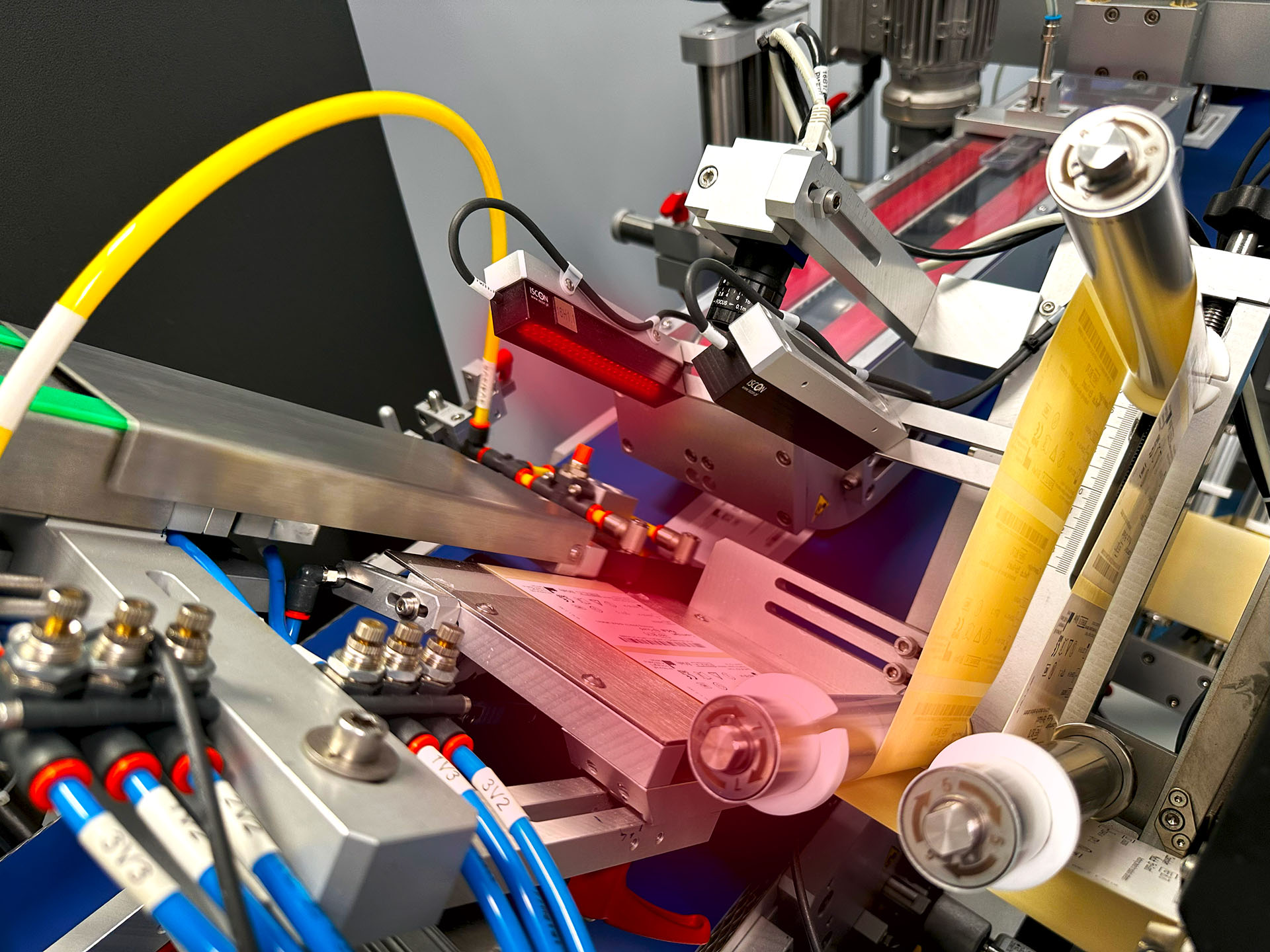

Another innovative technology used with the support of the WMS system is light technology, giving the possibility to conduct so-called “light”. pick by light.