Key information:

In our article, we will tell you how to create a consistent labeling system and introduce you to issues related to broad identification in healthcare based on 4 basic slogans: traceability, traceability, security and automation.

Self-adhesive labels for healthcare

Self-adhesive labels are by far the most popular labeling medium used in the medical sector. Thermal-transfer technology makes it possible to print small parts on the label by using high-resolution (up to 600 dpi) label printers.

The printed label is resistant to external forces (including the effects of chemicals, acids and alkalis), guaranteeing that the labels can be read in any conditions.

Barcode

or 2D code placed on the label is a guarantee of information in the process of manufacturing drugs, selling them, or administering them to a specific patient. The technology can also be used to identify medical equipment.

Choosing the right material

Sterilization, storage at extremely low temperatures in liquid nitrogen and other conditions often encountered in medicine can pose a significant threat to the durability of self-adhesive labels. The labels and printing ribbons offered by HKK Group meet the expectations of the medical sector.

We include labels that have been manufactured from special materials (e.g. made of polyolefin for use in cryochambers), polyester labels for protecting samples, or appropriate color ribbons that guarantee stable printing at extremely high or low temperatures.

Choosing the right printer

An important thing from the perspective of labeling system independence is to choose the right label printer. Depending on the volume of labels to be printed, we can choose desktop printers (for smaller volumes), semi-industrial printers (for medium volumes) and industrial printers (for the largest volumes).

Label printers can support two types of printing: thermal (for short-life labels) and thermal-transfer (for long-life labels – printing supported by a suitable transfer ribbon).

Examples of use

Laboratory samples

The way samples are stored determines the type of labeling. For permanent marking, it is worth using specialized self-adhesive labels printed using

label printers

with high resolution (due to the need to apply the labels to a relatively small area of the tube).

The label application itself can be done manually, but it can also be done automatically, using

print&apply label applicators.

Marking of medical containers

Label printers equipped with

automatic applicator

can apply self-adhesive labels to any type of container used in the medical industry.

These containers can be carriers for test tubes, and can also be part of the packaging of specialized tests, or drugs. The label applicator is capable of applying labels of various shapes – from classic quadrangular to cylindrical.

Cassette tests

Cassette tests gained popularity during the Covid-19 outbreak. Medicine and pharmacy use this type of tool in the diagnosis of many diseases (mainly viral) . Such tests are produced in an automated manner and then packaged in accordance with relevant regulations.

CAB brand application heads can support this type of production, applying up to 2,400 labels per minute. The shape and content of the label are selected according to individual customer expectations. It is possible to combine the infrastructure responsible for supervising production with the label printing system in such a way that the labels contain data of a variable nature.

What about logistics in the medical industry?

Marking with contactless RFID technology

RFID technology

like 2D code technology is proving very practical in the area of logistics support for the medical and pharmaceutical industries. The RFID tag hidden in a self-adhesive label makes it possible to read information (e.g. serial number or expiration date) in a contactless manner.

It is common to apply this technology to the labeling of bulk containers operating in a closed system (e.g., temperature-controlled drug containers). A definite advantage of using RFID technology is the ability to combine traditional technology (barcode, 2D code and RFID tag in one label).

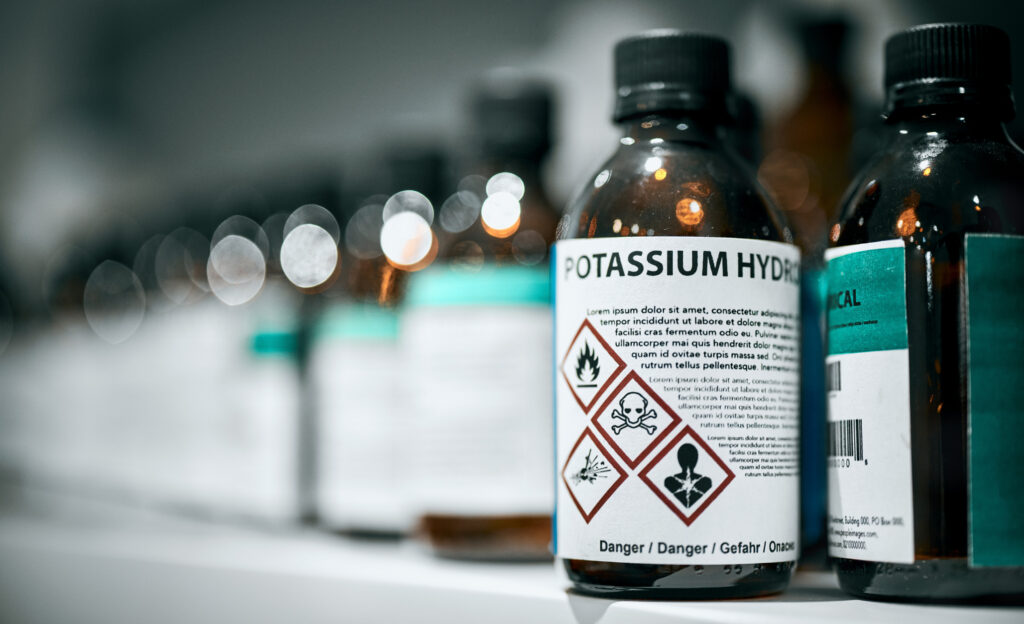

GHS labeling

Placing a hazardous substance on the market requires the use of appropriate warning labels that comply with GHS (Global Harmonized System) regulations. This system defines how hazardous substances (mainly chemicals, but also substances of other composition) are labeled.

As part of the GHS label, we use a series of pictograms placed on a colored background. The use of CAB XCQ brand label printers provides the ability to print two colors on a single device, making it possible to print GHS-compliant labels without using labels pre-printed at a label printer.

Computerization in health care and pharmacy

LIMS - medical laboratory management system

Medical and pharmaceutical facilities, like drug manufacturers, cannot operate without adequate support from an information system.

Systems like LIMS (medical laboratory management system) collect data on patients, drugs and procedures. A key element in the operation of a network of interconnected facilities is to use them in an integrated manner, based on uniform standards of required data.

The technology that supports this type of integration is definitely Automatic Identification Technology, which provides the ability to instantly and automatically read data from different facilities at the point where it will be critical.